- Packing - Handling - Logistics

- Conveying

- Magnetic separator

- allmineral Aufbereitungstechnik GmbH & Co.KG

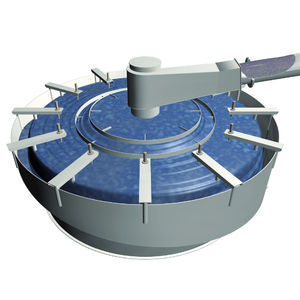

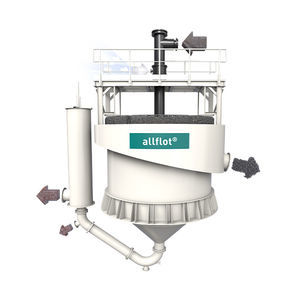

Magnetic separator allgauss®liquidsprocessfor ore

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic

- Separated substance

- liquids

- Application domain

- process, for ore

- Other characteristics

- high-intensity

- Filtration size

3 mm

(0.118 in)

Description

High-precision separation, excellent flexibility and energy efficiency.

The allgauss® is a straightforward, flexible and robust solution that delivers optimum results.

Cutting-edge technology and innovative control enable a wide variety of applications such as rougher, cleaner and 2-stage separation in an allgauss®

Throughput of up to 1,400 t/h in one machine

magnetic field strength of up to 15,000 gauss

Saves energy thanks to specially developed magnet system

Application areas of the allgauss® high-intensity magnetic separator

The allgauss® high-intensity magnetic separator is primarily used in the enrichment of haematitic iron ores. Additional applications include the extraction of heavy minerals and the separation of unwanted iron impurities from industrial minerals.

allgauss® high-intensity magnetic separators are deployed in the following applications:

Production of magnetic concentrates, e.g. ores of chrome, manganese, tungsten, zinc, nickel, tantalum/niobium, molybdenum and other weakly magnetic minerals.

Separation of impurities, e.g. from glass sand, talc, clay, kaolin, graphite, bauxite and other non-magnetic minerals.

Enrichment of high-quality pre-concentrates such as gold, platinum, chrome, manganese and iron from raw ores, slag or residues.

VIDEO

Catalogs

allgauss® brochure

4 Pages

alljig® brochure

8 Pages

Other allmineral Aufbereitungstechnik GmbH & Co.KG products

wet processing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.