Off-line programming software Almacam WeldsimulationCAD/CAMfor welding robots

Add to favorites

Compare this product

Characteristics

- Function

- off-line programming, simulation, CAD/CAM

- Applications

- for welding robots

- Type

- 3D

- Deployment mode

- off-line

Description

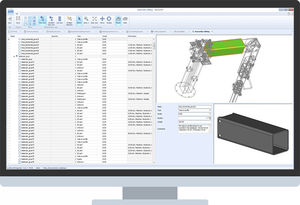

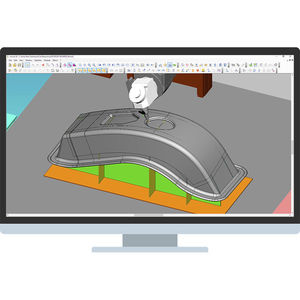

Almacam Weld - Offline programming software for arc-welding robots.

Almacam Weld, dedicated to the offline programming of arc-welding robots, allows you to optimize the utilization rate of your welding robots resulting in increased flexibility and improved productivity. A precursor over the past 20 years, Almacam Weld is now the leading solution in the field of arc-welding robot offline programming.

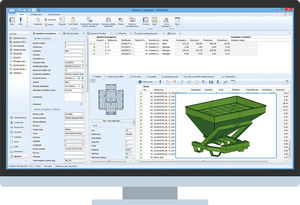

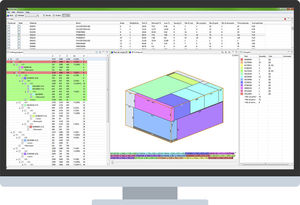

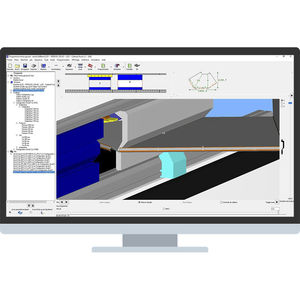

Through a graphic interface, Almacam Weld allows you to program a robot from a virtual scene and simulate its movements. The assemblies to weld, together with the tooling, are imported from a 3D CAD system.

Almacam Weld combines welder know-how together with programming and simulation tools that allow you to create programs in optimal conditions, and even to validate the design of a tooling or to study a cell set-up. Thanks to Almacam Weld you can generate programs that will require no further touch-ups in the workshop.

A post-processor specifically adapted to the controller generates the programs prepared with Almacam Weld in all the robot languages. The cell calibration and customization of the post-processor make it possible to integrate all the robot self-correction functions (shifting of trajectories via sensing or joint follow-up, laser camera, etc.) Almacam Weld also manages multi-robot cells.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Computer-aided design software

- Online software

- 3D software solution

- Simulation software

- Programming software

- 2D software

- Optimization software solution

- Modeling software

- High-performance software solution

- CAM software

- Internet-based software

- CAD/CAM software

- Milling software

- Cutting software

- Cutting machine software

- 2D/3D software

- Off-line software

- Robot software

- Nesting software

- Sheet metal software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.