- Packing - Handling - Logistics

- Conveying

- Continuous pneumatic conveying system

- ALPHA AUTOMATISMES Sarl

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Aspiration pneumatic conveying system DF INOX 316continuouspositive-pressurefor bulk materials

Add to favorites

Compare this product

Characteristics

- Type

- aspiration, continuous, positive-pressure

- Product applications

- for bulk materials, for powders, for plastics, for abrasive media, parts, for food, cap, sand, for granulates, for the food industry, for industrial applications, for food products, for bulk materials, fly ash, chemical process, powder, for dairy products, for solids, for cohesive product, dry bulk material, for the pharmaceutical industry, handling, cyclone, for abrasive products, vacuum, for crown caps, for high-temperature applications, industry, for chemical products, food

Description

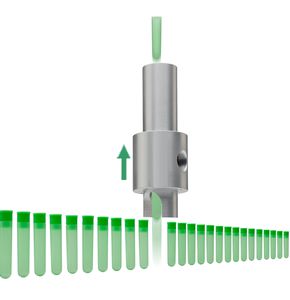

- Specialized in-line venturi for pneumatic conveying, without seal, made of 316L stainless steel

- Ø of passage: from 4 to 75 mm

Features:

- In-line venturi with straight duct specialized for pneumatic conveying of material and objects

- Fully static, instant start and stop

- To be installed in line on a flexible or rigid transport pipe

- Capacity : from 0 to 10 Kg/min of transported material

Applications :

- Transport of powders, granules and objects

- Cleaning

- Feeding of machines

- Evacuation of waste

- Ejection of defective materials on a conveyor

Materials :

- Body: 316L stainless steel

- Seals: Sealless or elastomer

Technical specifications:

- Fluid: compressed air

- Optimum pressure: 5.5 bar

- Pressure range: 0 to 10 bar

- Temperature range: - 50° to + 250°C

Further information:

Pneumatic conveying nozzles offer simple, reliable and economical conveying of powders, granules and objects.

The conveying power is adjustable by varying the inlet pressure.

They are compact and can be installed close to the work area for maximum efficiency.

The nozzles are available in 10 standard models from Ø 3.8 to 75 mm internal passage.

Powered by a solenoid valve and without inertia, they consume energy only during the use phase.

The high outlet pressure allows the use of a filter, cyclone or other system to recover the material conveyed.

For the transport of non-aerated compact powders, use a coaxial suction pipe with external air intake (schematic diagram on request).

VIDEO

Catalogs

No catalogs are available for this product.

See all of ALPHA AUTOMATISMES Sarl‘s catalogsOther ALPHA AUTOMATISMES Sarl products

Pneumatic conveying system

Related Searches

- Pneumatic conveying system

- Powder pneumatic conveying system

- Aspiration pneumatic conveying system

- Continuous pneumatic conveying system

- Bag unloader

- Bulk products pneumatic conveying system

- Vacuum pneumatic conveying system

- Handling pneumatic conveying system

- Positive-pressure pneumatic conveying system

- Food pneumatic conveying system

- Granulate pneumatic conveying system

- Bulk material pneumatic conveying system

- Pneumatic conveying system for the pharmaceutical industry

- Abrasive product pneumatic conveying system

- Pneumatic conveying system for industrial applications

- Pneumatic conveying system for the food industry

- Powder pneumatic conveying system

- Food pneumatic conveying system

- Plastic pneumatic conveying system

- Solid pneumatic conveying system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.