- Metrology - Laboratory

- Optical Component

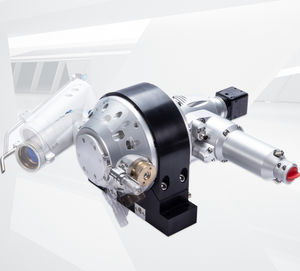

- Pulsed laser head

- ALPHA LASER GmbH

Pulsed laser head LASERSPINDLE-C/CLfiberinfrareddrilling

Add to favorites

Compare this product

Characteristics

- Operational mode

- pulsed

- Technology

- fiber

- Spectrum

- infrared

- Applications

- drilling, process

- Other characteristics

- single-mode, water-cooled, rotary

- Power

150 W

- Wavelength

1,064 nm, 1,070 nm

Description

The LASERSPINDLE-C/ CL is used for notching, scoring and drilling, i.e. for creating predetermined breaking points on rotationally symmetrical components made of brittle metals, e.g. on connecting rods or crankshaft housings (insertion depth -1m). The process head is completely water-cooled and therefore suitable for continuous operation.

Ideal for operating the LASERSPINDLE-C/CL is the use of the AL-RACK 150 F, which contains a 150 W single mode laser module as well as the control of the optics including the laser source.

The targeted fracturing (cracking) of connecting rods at predetermined fracture points (laser scribing) ensures a high quality of the fracture surfaces on both halves of the component. This is crucial for the high accuracy of fit required for the two parts during final assembly. Thus, after assembly, the fracture is hardly visible. The fracture separation process with preceding laser scribing thus permits one-piece and thus cost-effective connecting rod production.

Catalogs

No catalogs are available for this product.

See all of ALPHA LASER GmbH‘s catalogsRelated Searches

- Laser head

- Pulsed laser head

- Compact laser head

- Infrared laser head

- Fiber optic laser head

- Fiber optic laser system

- Pulsed laser system

- Welding laser head

- CW laser head

- Process laser system

- Compact laser system

- CW laser system

- Infrared laser system

- Process laser head

- Solid-state laser system

- Drilling laser head

- Gas laser head

- Industrial laser system

- Welding laser system

- Nd:YAG laser system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.