- Metrology - Laboratory

- Optical Component

- Continuous wave laser head

- ALPHA LASER GmbH

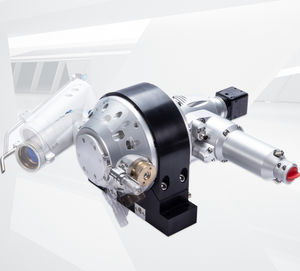

Pulsed laser head Laserhead-PCWfibergas

Add to favorites

Compare this product

Characteristics

- Operational mode

- pulsed, CW

- Technology

- fiber, gas

- Spectrum

- infrared

- Applications

- for welding, process

- Other characteristics

- compact, water-cooled

- Power

4,000 W

- Wavelength

1,064 nm, 1,070 nm

Description

Laser powder deposit welding is a generative manufacturing process. Using a carrier gas, metal powder is fed through three nozzles into the laser focus and melted onto a workpiece. If the nozzle is moved relative to the workpiece, surfaces, lines or any geometries can be applied.

By coating suitable materials in multiple layers, almost any layer thickness can be achieved, and 3D volumes are also possible.

For visual observation as well as for its adjustment, the LASERHEAD-P is equipped with a coaxially guided Ethernet camera with integrated illumination.

The process head is very compact and lightweight, as the control of the electronic components is integrated. The housing is completely water-cooled - continuous operation at maximum performance is thus guaranteed.

For perfect powder transport to the process head, we recommend the ALPHA LASER powder feeder AL-PF.

Catalogs

No catalogs are available for this product.

See all of ALPHA LASER GmbH‘s catalogsRelated Searches

- Laser head

- Pulsed laser head

- Compact laser head

- Infrared laser head

- Fiber optic laser head

- Fiber optic laser system

- Pulsed laser system

- Welding laser head

- CW laser head

- Process laser system

- Compact laser system

- CW laser system

- Infrared laser system

- Process laser head

- Solid-state laser system

- Drilling laser head

- Gas laser head

- Industrial laser system

- Welding laser system

- Nd:YAG laser system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.