- Packing - Handling - Logistics

- Packing and Packaging

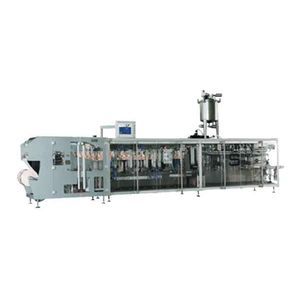

- Horizontal bagging machine

- ALPHA-PACKEUROPE / SCELLINOX

- Products

- Catalogs

- News & Trends

- Exhibitions

Horizontal bagging machine AP-12BTflow-packrotaryPLC-controlled

Add to favorites

Compare this product

Characteristics

- Type

- horizontal

- Technology

- flow-pack, rotary

- Operational mode

- PLC-controlled

- Packaging

- for doypack

- Product applications

- oil, pasta, for solids, for liquids, for granulates, detergent

- Other characteristics

- 3-seal, 4-seal

- Throughput

Min.: 20 p/min

Max.: 40 p/min

Description

The AP12BT is a 12-station automatic rotary machine for doypack bags with spout filling for liquids such as milk, yoghurt, fruit juice, oil and condiments, detergent, chemicals, etc.

It is controlled by an advanced Panasonic PLC control system through a 7″ colour touch screen (up to 20 memorisable programs) that can easily set and modify packaging parameters, display production data and any machine errors (self-diagnostics can be viewed directly from the screen).

The packaging process begins from the loading of the bag, its positioning inside the machine, the coding, the filling, the closing of the cap, the cooling down and at the end the bag is released on an integrated outfeed conveyor.

In order to allow a high productivity there is the possibility to insert from 2 to 8 filling systems (speed up to 14.000 pcs/hour) and to insert an automatic loading system of the bags, digital printers, etc.

TECHNICAL DETAILS

• Panasonic PLC

• 7″ Kinco colour touch screen

• Manual or automatic bag loading system

• Entirely made of Aisi 304 (aisi 316 on request)

VIDEO

Other ALPHA-PACKEUROPE / SCELLINOX products

DOYPACK PACKAGING MACHINES

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Bagging machine

- Automatic labelling machine

- Filler for the food industry

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Food product filling machine

- Bulk material bagging machine

- Bottle labeling machine

- Bagging machine for the food industry

- Volumetric filler

- Horizontal bagging machine

- Side labelling machine

- Sealer

- Bag packing machine

- Granulate bagging machine

- Powder bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.