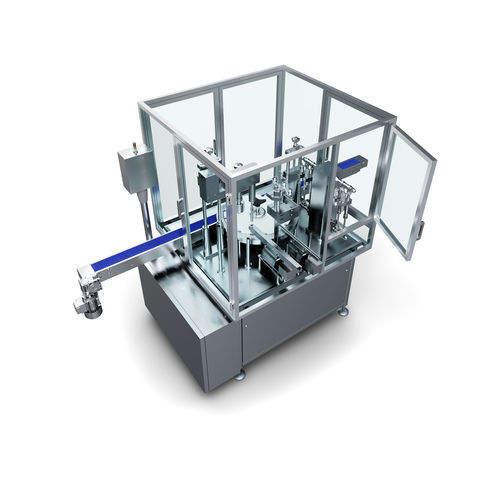

Automatic filling and capping machine PEGASUSsyringerotaryvolumetric

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- syringe

- Type

- rotary, volumetric

- Other characteristics

- industrial

Description

Extremely versatile filling and capping machine, with capacities from 1 to 2000I

production available from 500 to 6000 pcs / h.

Automatic filling and capping machine volumetric precision system is extremely flexible, as expected from 1 to 8 syringes with capacity from 1ml to 2000 mI.

with production from 500 to 6000 PCs/h.

The machine can be used with various kinds of products:

liquids, slurries and liquid with plastic bottles, glass or metal.

Chemical-pharmaceutical and cosmetic industry circular machine model PEGASUS is optimal use as it allows a rapid and accurate filling of the bottles, suitable for all types of bottle and product.

TECHNICAL DATA

Sturdy stainless steel frame

Feeding bottles, by star step-by-step

Volumetric progressive independent stations

Check incoming bottles

Group 1 to 8 stainless steel syringes, Teflon and glass

Cap feeding vibration system

Speed adjustable by inverter

Capping system with heads of various types of system to: edgebandering machine, Edge Bander, screwing machine, wrench, thread cutter crimper.

Loading and unloading group bottles according to customer requirements

Anodised aluminium or stainless steel protective cover with safety sensors

Extremely quiet solution with maximum compliance with noise pollution with the use of interconnected cam

Rapid format change

Very open system to allow the use of different sizes, shapes and abilities, thanks to the versatility of the star which allows using different bottles without touching the filling and capping apparels

VIDEO

Related Searches

- Automatic labelling machine

- Labeller for the pharmaceutical industry

- Labeler for the cosmetics industry

- Filling and capping machine

- Packaging labelling machine

- Automatic filler and capper

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and closing machine

- Bottle filling and capping machine

- Industrial filling and capping machine

- Rotary filling and capping machine

- Volumetric filler and capper

- Filling and closing machine for pharmaceutical applications

- Pharmaceutical product filling and sealing machine

- Bottle filling and closing machine

- Filling and closing machine for the cosmetics industry

- Cosmetic product filling and sealing machine

- Pharmaceutical product filling and capping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.