- Production Machines

- Cutting Machine

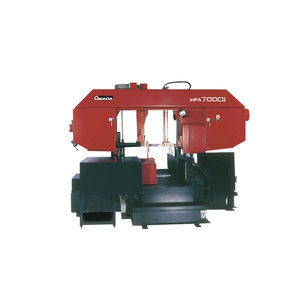

- Band saw

- Amada Machine Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

Band saw PCSAW 530 X/AXfor steelfully-automaticCNC

Add to favorites

Compare this product

Characteristics

- Technology

- band

- Treated material

- for steel

- Operational mode

- fully-automatic, CNC

- Other characteristics

- precision, hydraulic, servo-driven

- Round piece diameter

Min.: 30 mm

(1 in)Max.: 530 mm

(21 in)

Description

Band saws with pulse cutting technology have been designed for economical use under toughest production conditions.

For Users who demand the highest demands on cutting performance and quality, based on decades of experience, the optimum approach between tool and machine was developed.

The pulse cutting technology developed by AMADA hasrevolutionised band sawing like no other process.

Predefined loading and unloading of the band saw blade in thefeed direction generates a wave-like up-and-down motion of thesaw band that has a positive effect on the sawing process.

The main advantages are:

■ low cutting resistance

■ more effective tooth contact

■ low thermal load due to shorter chipping and improved coolingaction of the cooling lubricant

■ larger band saw blade service life

Basically, it is possible to use either carbide tipped orbimetal bandsaw blades in the metal distribution.

The corresponding sawing parameters for more than 200 materialsare stored in the CNC controller for both band types.

If special materials such as Hastelloy or Inconel are sawed, theAX version is recommended where saw feeding takes placevia a precision, servo-electric ball screw drive. In contrast, thePCSAW 530 X model operates with the proven servo-hydraulicAMADA saw feed.

Catalogs

No catalogs are available for this product.

See all of Amada Machine Tools‘s catalogsRelated Searches

- Metal sawing machine

- Automatic sawing machine

- Circular sawing machine

- Band sawing machine

- Saw blade

- Horizontal sawing machine

- Cut-off sawing machine

- Circular saw blade

- Profile sawing machine

- Precision sawing machine

- Tube saw

- Miter sawing machine

- Steel sawing machine

- Metal saw blade

- Semi-automatic sawing machine

- Cutting saw blade

- Vertical sawing machine

- Electric sawing machine

- Carbide saw blade

- Hydraulic sawing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.