- Industrial machines and equipment

- Welding and Assembly

- Arc welding head

- AMADA WELD TECH Inc.

- Products

- Catalogs

- News & Trends

- Exhibitions

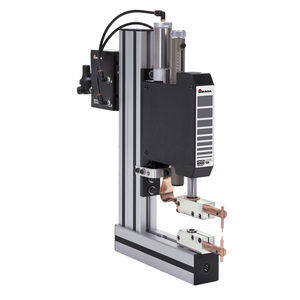

Arc welding head KN-200A pneumaticautomatic

Add to favorites

Compare this product

Characteristics

- Technique

- arc

- Other characteristics

- automatic, pneumatic

Description

The KN-200A-Single weld head has been extensively proven in industrial environments around the world and is regarded as the “dependable workhorse” of the industry. Built in the USA, its proprietary fast force follow-up feature eliminates weld expulsion, preventing entrapment of ejected materials in projection welded electronic devices – a common cause of PIND (particle impact noise detection) failure.

Single cylinder design delivers 250 – 1250 lb (113 – 568 kg) of weld force.

Designed to accommodate a variety of metal projection welding applications including sensors, frequency devices, filaments, heating elements, photonic packages, strain gauges and transducers.

•Robust, low maintenance die set design

•Fast force follow-up feature maintains force during weld eliminating weld expulsion

•Rigid construction using a 25 micron matched linear ball bearing bushing and tie rod for precise positioning and planarity

•Simple actuation using Benchmark’s SS-1 pneumatic weld head controller

•Can be configured to be used with any manual or automatic welding system

Catalogs

No catalogs are available for this product.

See all of AMADA WELD TECH Inc.‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Welder

- Arc welder

- Laser welding system

- Metal welding system

- Precision welding system

- Arc welding system

- DC welder

- Three-phase welder

- Single-phase welder

- TIG welder

- Manual welding system

- Resistance welding system

- Standalone welding system

- Soldering machine

- Compact welding system

- CNC welding system

- Welding generator

- Fiber laser welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.