- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Pneumatic fitting

- American Flow Control

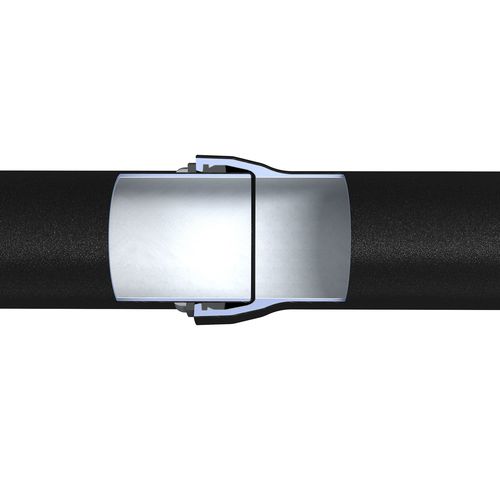

Pneumatic fitting push-to-lock

Add to favorites

Compare this product

Characteristics

- Applications

- pneumatic

- Attachment

- push-to-lock

- Diameter

Min.: 4 in

Max.: 64 in

Description

AMERICAN Fastite joint push-bar pipe, furnished in sizes 4" through 64", allows the AMERICAN Fastite joint to be used in trenchless installations using direct jacking or pushing (including high load installations such as microtunneling and some pipe-bursting applications).

Fastite push-bar pipe employs an economical adaptation of the premier AMERICAN Fastite joint to transfer jacking loads from the pipe barrel directly to the face of the bell. It consists of a high-strength alloy steel ring – the “push-bar” – shop welded to the standard Fastite pipe spigot. This ring is made of the same material that has been used successfully in AMERICAN’s Lok-Ring and other restrained joints since 1967. A cushioning compression ring, made of compressible wood products, fits between the push-bar and the pipe bell for added assurance of load distribution. The pipe comes in standard 20’ or less nominal laying lengths and carries the standard Fastite joint pressure ratings.

During installation, Fastite joint push-bar pipe is jacked or pushed with the spigots ahead. This allows for any debris remaining from the pipe bursting or pipe jacking operation to flow smoothly over the bell of the Fastite joint.

Catalogs

No catalogs are available for this product.

See all of American Flow Control‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.