- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Asset management software IMAGEPro AM monitoringindustrialautomated

Add to favorites

Compare this product

Characteristics

- Function

- asset management, monitoring

- Applications

- industrial

- Type

- automated

Description

Refractory-lined vessels and furnaces are common in industrial applications such as petrochemicals, steel production, processing and heat treatment.

Over time, refractory deteriorates to a point where it has to be relined. Traditionally, the timing of a reline is ad-hoc and based on guidance from licensors, and previous experience of refractory issues.

However, this approach is not data-driven and can lead to critical and dangerous leaks of toxic gases, or an explosion resulting in plant damage, income loss and in the worst case, injury to personnel.

The continuous maintenance and monitoring of vessels and furnaces are therefore essential to production reliability and a plant’s throughput.

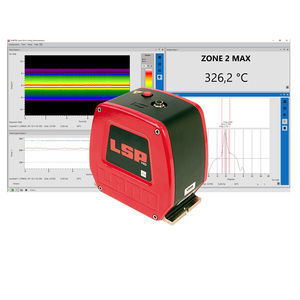

Automated monitoring of the shell temperatures of vessels’ and furnaces’ critical areas enables their condition and safety to be continuously assessed to avoid leaks or identify dangerous outbreaks.

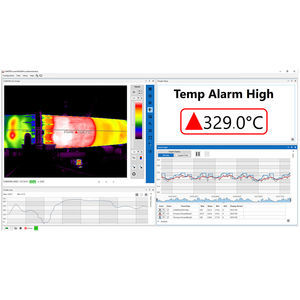

LIVE THERMAL CAMERA MONITORING

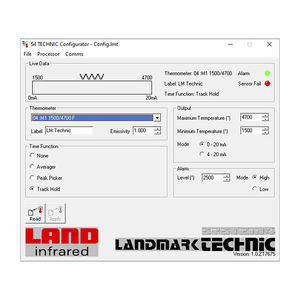

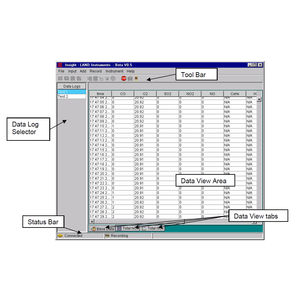

An overview of all cameras installed, grouped by areas, for 24/7 continuous monitoring, data trending and logging. Up to 16 cameras can be connected to and processed at each IMAGEPro AM workstation.

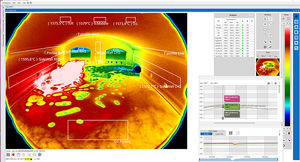

CUSTOMISED AREA & THERMAL CAMERA STATUS OVERVIEW

A customised overview provides a virtual view of the installed areas and cameras and their actual conditions. By selecting a camera, the live camera view window will open and show actual alarm status and conditions for further analysis.

ACTIVE AND HISTORICAL ALARMS & STATUS

All alarms (active and historical) and system status are logged to the integrated database and monitored continuously. Active alarms are monitored and can be easily acknowledged in the system.

Related Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Land Windows software

- Control software solution

- Real-time software solution

- Land monitoring software

- Interface software

- Measurement software

- Industrial software solution

- Visualization software solution

- Automated software

- High-performance software solution

- Data acquisition software

- Data analysis software solution

- Android software solution

- Alarm software

- Process control software solution

- Statistical software

- Imaging software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.