- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

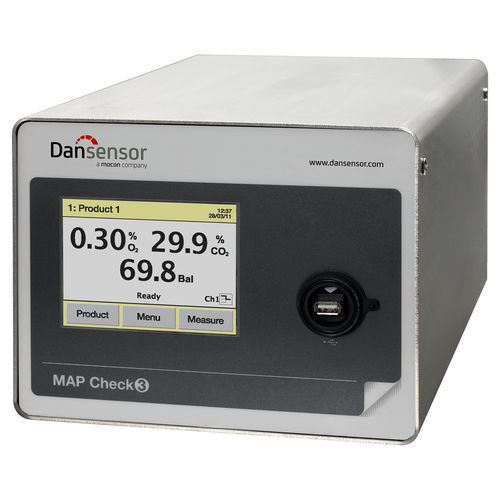

Oxygen analyzer Dansensor MAP Check 3carbon dioxideCO2/02monitoring

Add to favorites

Compare this product

Characteristics

- Measured entity

- oxygen, carbon dioxide, CO2/02

- Application domain

- monitoring, process, for quality control, for the food industry, for pharmaceutical products, for cosmetic products

- Measured value

- concentration

- Configuration

- for integration, in-line

- Mode of use

- automatic

- Technology

- NDIR, zirconia

- Other characteristics

- real-time, control

Description

A smarter way to control your MAP process

MAP is the future. But companies using more gas than necessary to produce MAP products run the risk of becoming history.

That’s why we’ve designed this gas analyzer to be so precise. With the MAP Check 3, the gas target you set is the gas dosage you get. It eliminates the all-too-common problem of well-intentioned operators using too much gas, without realising its effect on production costs.

The only thing the MAP Check 3 increases is your flexibility. It lets you combine monitoring of gas content on a vertical or horizontal flow packaging machine with real-time control of package flushing via an advanced GasSave function. For most manufacturers, this translates into a 20-50% decrease in gas consumption!

It also improves reliability and efficiency. Unlike random, off-line quality control, on-line quality assurance with the MAP Check 3 means that every package is tested — far more quickly and efficiently than with manual testing. And if there’s a problem, production stops automatically, helping to avoid recalls or the need to repack entire batches. Read how a meat producer of processed food is saving gas.

VIDEO

Catalogs

Related Searches

- Gas analyser

- Concentration analyser

- Monitoring analyser

- Liquids analyser

- Desktop analyzer

- Gas sensor module

- Automated analyzer

- Dust analyzer

- Process analyser

- Portable analyser

- Continuous analyser

- Integration analyser

- Real-time analyser

- Compact analyser

- Oxygen analyser

- Laboratory analyser

- Electrochemical gas sensor module

- Digital analyser

- Industrial testing system

- NDIR analyzer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.