- Production Machines

- Textile machinery

- Chain stitch sewing machine

- AMF Reece CR, s.r.o.

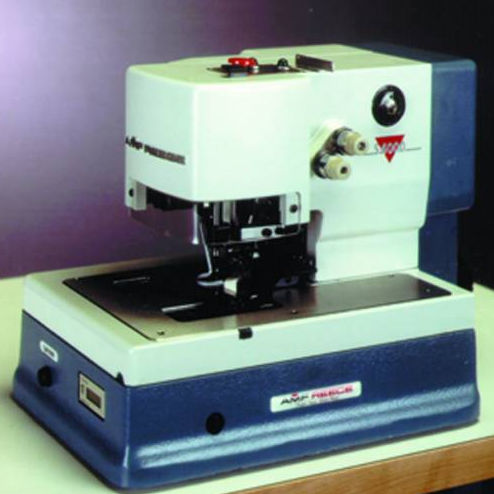

Chain stitch sewing machine S-4000 BHbuttonholefixedelectronic

Add to favorites

Compare this product

Characteristics

- Stitch type

- chain stitch

- Applications

- buttonhole

- Configuration

- fixed

- Control

- electronic

- Options and accessories

- high-speed

Description

The chainstitch straight buttonhole machine offers unsurpassed speed and quality in the production of straight buttonholes on all types of garments and material. The chainstitch buttonhole provides increased production with no bobbin changes. The elasticity of the chainstitch also provides the flexibility needed for many fabrics such as knitwear. The high sewing speed of the chainstitch straight buttonhole machine and the short sewing cycle increase productivity and the single pedal electronic start reduces operator fatigue. The S-4000 BH chainstitch straight buttonhole machine can be programmed to sew single or double cycle sew. Changes to the length of the buttonhole are made by a single screw adjustment located on the machine bed.

Main Features

Electronic Stop and Start Motion

The electronic start and stop motion extends machine life and improves machine reliability by eliminating the stop motion and clutch mechanisms.

Patented Mechanisms

The S-4000 contains six patented mechanisms:

- Needle Bar Drive

- Looper Drive

- Main Cam

- Double Lobe Cam

- Bite Mechanisms

- Feed Mechanisms

Fully Enclosed Mechanism

DC Drive Motor is fully enclosed within the head casting, eliminating the need for an under the table mounted clutch motor, pulley, belt and brake. This reduces required maintenance and eliminates oil and dust around the working area.

Microprocessor Control

The microprocessor control ensures maximized ramp-up and ramp-down speeds to achieve minimized cycle times.

Productivity & Flexibility

Chainstitch buttonholing provides increased productivity with no bobbin change.

VIDEO

Other AMF Reece CR, s.r.o. products

Chainstitch Special Application Machines

Related Searches

- Fixed sewing machine

- Single-needle sewing machine

- Fabric sewing machine

- Automatic sewing machine

- Lockstitch sewing machine

- Single-thread sewing machine

- Sewing machine with thread trimmer

- High-speed sewing machine

- Twin-needle sewing machine

- Chain stitch sewing machine

- Electronic sewing machine

- Programmable sewing machine

- 2-thread sewing machine

- Pattern sewing machine

- Jean sewing machine

- Sewing machine with automatic lubrication

- Cylinder arm sewing machine

- Overlock stitch sewing machine

- Mechanical sewing machine

- Hemming line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.