Stitching Template Manufacturing System Autotrak 84-78

AMF Reece pioneered template stitching in the 1960s, and the Autojig system remains the unchallenged world leader for assembling garment components ranging in size from pocket flaps to topcoat foreparts.The Autotrack is a Special device for manufacturing your own stitching templates for AMF Reece Autojig machines.

Main Features

Compliments the AMF Reece Autojig System

84-78 Autotrak enables Autojig system users to maintain full control over template cost and delivery time with easy on-site manufacturing of stitching templates. The system produces robust, accurate stitching templates (jigs) of proven durability for small or large scale production of precision-made garment components ranging from pocket flaps to jacket foreparts.

Benefits of Autotrak

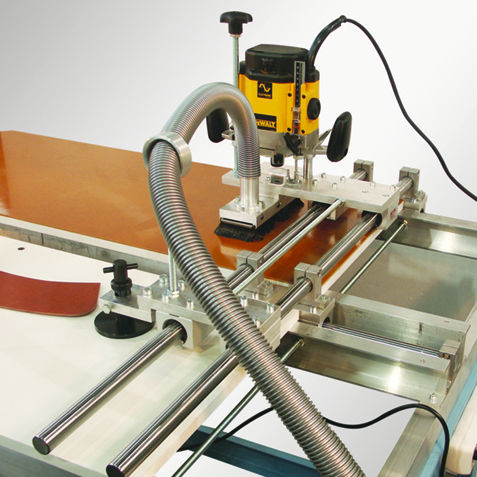

robustly constructed lightweight aluminium alloy router head moves in the “X” and “Y” directions on hardened steel shafts fitted with linear recirculating ball bushings, giving ultra-smooth movement ideal for machining the template

bushings are fitted with lip seals to exclude dust, for durability and easy maintenance router speed is variable to ensure optimal cutting of different materials

at 2 kWh, the router unit is more powerful than previous models

depth of cut is adjustable and can be pre-set to 3 positions for easier working

cutter is fully guarded and dust is continuously extracted

cutting tools and consumable items can be obtained from local suppliers, if necessary