Primary shredder RSS 120-Msecondarydouble-shaftfor non-ferrous materials

Add to favorites

Compare this product

Characteristics

- Type

- primary, secondary

- Number of shafts

- double-shaft

- Application

- for non-ferrous materials

- Other characteristics

- rugged, mobile, with conveyor

- Output

Min.: 0 t/h

(0 lb/s)Max.: 180 t/h

(110 lb/s)- Operating weight

35,500 kg

(78,264.1 lb)

Description

The Ammann RSS 120-M is a shredder, iron separator and screener – all built into a single machine. It is ideal for recycling asphalt, from milled materials to asphalt slabs and large chunks. The RSS 120-M features patented technology that utilises milling cutters with interchangeable teeth for efficient and gentle crushing. The technology is both powerful and fuel efficient, and complements other environmental friendly efforts built into the machine, including minimised sound and dust emission levels.

Fast replacement of wear parts

Robust, long-life wear protection

Fast change of screen mashes

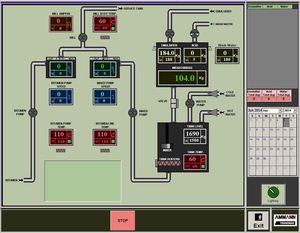

Notification system for intuitive troubleshooting

Track-mounted for mobility and autonomy

Standard transport by flatbed truck

From installation to production in 30 minutes

Primary shredder

Iron separator

Screening machine with two screen decks

Oversize grain recirculator

Secondary shredder

Smooth and gentle shredder preserves grain sizes of input material

Processed material allows higher addition of recycling material to asphalt mix

Hydraulic fingers ensure continuous load

The shredder motor stops when clogging occurs and reverses

Slowly rotating primary shredder for high output and fewer fines

Hydraulically adjustable gap in primary shredder

Diesel engine with 256 kW

Power generator with 400 KVA

Drive motors electrically powered

High fuel efficiency

Catalogs

No catalogs are available for this product.

See all of Ammann‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.