- Metrology - Laboratory

- Inspection and Monitoring

- Data collector

- Amper Technologies, Inc.

- Products

- Catalogs

- News & Trends

- Exhibitions

Data collector

Add to favorites

Compare this product

Description

Collect real-time data on any machine type—no PLC integration required

Installation is simple

Clip sensor to any machine's power supply

Connect Wi-Fi or cellular enabled Gateway and allow the system to calibrate

Access real-time data from any device

Increase productivity with visual management boards

At a glance, easily understand what machines are currently in production, downtime reasons, good vs. scrap parts, OEE and more.

“To have all this data in real-time at our fingertips… I just couldn’t live without [Amper] at this point.”

Nick Sinati, President of Belden Universal, MakingChips Podcast

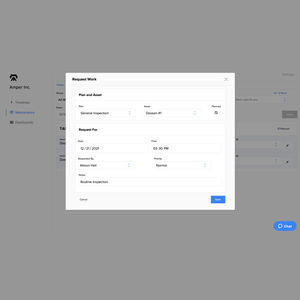

Track downtime reasons

When a machine goes down, operators can log downtime reasons. Monitor which operators are logging reason codes or get notified if labels aren’t promptly applied.

Report on utilization regardless of variable production time

Indicate whether a machine is scheduled to run a certain day or shift. Easily mass label downtime instances like holidays or other scheduled plant shutdowns. Remove certain downtime reason codes like Setup, Lunch or Holiday from your overall available production time.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.