- Products

- Catalogs

- News & Trends

- Exhibitions

Articulated robot SCARAdelta6-axis

Add to favorites

Compare this product

Characteristics

- Type

- articulated, SCARA, delta

- Number of axes

- 6-axis

- Function

- handling

- Mounting

- floor-mounted

Description

Mounted (fixed) robotics, or multi-axis systems, incorporate high-performance technologies to support the end system solution used in modern manufacturing installations. Examples of mounted robots include cobots, articulated robots, SCARA, delta robots, and many other CNC machines which may be rail mounted, wall mounted, floor mounted, or body mounted.

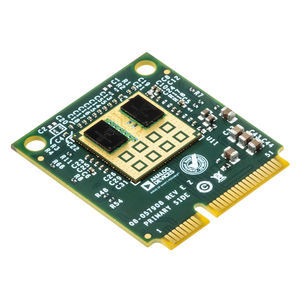

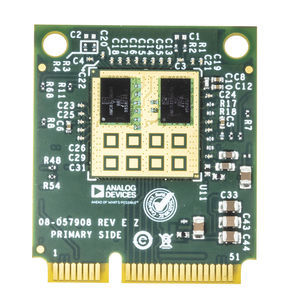

Analog Devices’ mounted robotics portfolio is backed by decades of innovation and domain expertise that enables more intelligent and flexible robots and cobots, step-changing productivity and efficiency, and modular designs from sensors to cloud.

Value and Benefits

Personalization is driving the need for flexibility in manufacturing systems, requiring fast reconfiguration to account for real-time changes in product mix, output volume, or process sequence. We offer full systems encompassing multiple technologies for subsystem elements from motor drive and servo systems to sensing and connectivity. With the aid of strong partner collaboration, we are enabling our technologies beyond silicon by embracing system services, applications software, firmware, and much more.

Offers complete, board-level motor control solutions that leverage proven hardware building blocks from ADI Trinamic

Features real-time connectivity to optimize for more advanced control and human engagement

Enables long term reliable and robust automated tool changing

End Effectors and Tools

Smart grippers and end effectors extend the range of tasks robots can perform. With flexibility and productivity being key objectives, ease of use and quick tool changes are possible with plug and play connector interfaces.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Analog Devices‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.