- Products

- Catalogs

- News & Trends

- Exhibitions

Warehouse AMR handlingcollaborativebattery-powered

Add to favorites

Compare this product

Characteristics

- Applications

- handling, for warehouse

- Specifications

- battery-powered, collaborative

Description

The evolving smart factory is deploying mobile robotics alongside humans at an accelerating pace. To ensure safety, productivity, and longevity in the smart factory of the future, this mobile robotic workforce must increasingly comprehend and interact with its environment and human colleagues.

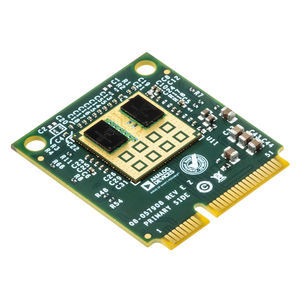

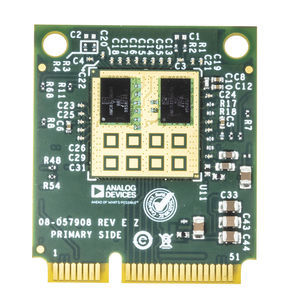

Analog Devices offers high-performing perception sensing solutions that enable real-time awareness of the robotic system, including simultaneous localization and mapping (SLAM) for best-in-class safe navigation of AMRs (autonomous mobile robots), AGVs (automated guided vehicles), and cobots (collaborative robots) in factories and warehouses. Our mobile robotics innovations include more compact, safe, and energy efficient servo drives that reduce robot size and power consumption, resulting in more productive, lower emissions factories. Our technologies also include optical and magnetic encoders for joint rotation and angular position feedback.

Value and Benefits

Material handling processes within the factory are becoming smarter and more flexible using AMRs. Leveraging our MEMS sensing, intelligent processing, 3D time-of-flight (ToF) and machine learning technology, AMRs are safely and autonomously moving materials without the need for physical guides or markers. Our Power by Linear™ portfolio of high-performance power management solutions for power conversion as well as battery management address the challenge of efficient battery management, critical to mobile robots to maximize use between charging. Wheel drive solutions are designed to deliver precise motion control, optimized for accuracy and efficiency of movement.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Analog Devices‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.