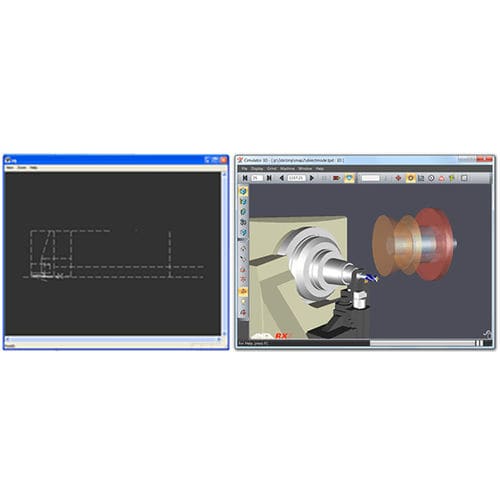

3D motion software AMCorefor CNC machinesWindows

Add to favorites

Compare this product

Characteristics

- Function

- 3D motion

- Applications

- for CNC machines

- Operating system

- Windows

Description

AMCore allows you to program CNC motion control software. ANCA Motion’s CNC systems are comprised of both hardware and software, which have evolved through design and refinement for over 40+ years. From the introduction of the hand wheel, which allowed users to easily step forward and back through a program, through to developing and implementing the patented soft axes, our achievements have cemented our status as an industry leader in machine system development.

Core kinematics allows machine joints to be mapped to real world machine coordinates, simplifying a complex machine into a number of easy-to-command axes. Our MPG feed, retrace and active program edit features allow you to correct points immediately during a dry-run without the need to restart. Soft axes allow complex axis combinations to be programmed using a virtual or software axis.

AT A GLANCE

- Software based CNC architecture

- System runs on standard PC hardware

- EtherCAT® Fieldbus connects to standard Ethernet port

- Runs purely within the Microsoft Windows OS

- Patented Soft (Virtual) Axes hand-wheel feed (MPG)

- CNC Connect to allow custom advance applications to be developed

CONCURRENT LOGICAL MACHINES

- Control multiple logical machines concurrently through individual channels

- Multiple machines can be operated autonomously while their specific NC programs are executed from a single unit Synchronised operations can be easily achieved and maintained

- Multiple machines can be operated autonomously while their specific NC programs are executed from a single unit

Catalogs

Product Catalogue

41 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.