- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

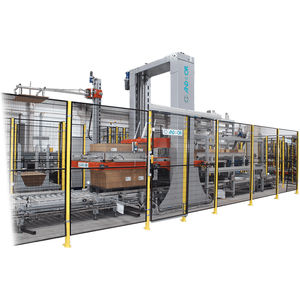

Robotic tray packer palletizer ECAM + PFC + RPZautomaticfor bottlesblow molding industry

Add to favorites

Compare this product

Characteristics

- Type

- robotic

- Operating mode

- automatic

- Product applications

- for bottles, blow molding industry, bottling industry, for the packaging industry

Description

Flexible combination of desk, tray former and robot.

ECAM/ECA: layer configuration desk over motorized belt or metallic base. Motorized frame to accompany and insert bottles into sheet or tray.

PFC: this automatic tray former folds and glues cardboard sheets to form trays (hot melt System).

RPZ: palletizer robot with rotary column and customized gripper to pick up sheets, trays, top frames or pallets.

Machine autonomy: depending on configuration.

Type of packaging: upside tray, inverted tray, cardboard sheet, top frame.

ECA desk: steady bottles, medium production rates.

ECAM desk: steady and unsteady bottles, medium or high production rates.

Pallet height: up to 3m.

Additlonal equipments:

• Tray, top frame or sheet warehouses.

• Automatic tray former with hot glue application.

• Automatic plastic sheet supply between layers (from roll of lm) to protect the bottles neck from touching the cardboard.

• Pallet warehouse.

• Output roller or chain conveyor for pallet accumulation or transportation to wrapping/strapping area.

• Automatic wrapping machine integration.

• Automatic strapping machine integration.

• Mobile carriage to cover different palletizing lines for transporting pallets long-distance without obstructing transit areas with x conveyors

VIDEO

Catalogs

No catalogs are available for this product.

See all of AND & OR‘s catalogsRelated Searches

- Industrial robot

- Wrapping machine

- Bagging machine

- Handling robot

- Automatic bagging machine

- Automatic wrapping machine

- FFS bagging machine

- Strapping machine

- Pallet wrapping machine

- Palletizer

- Automatic strapping machine

- Horizontal bagging machine

- Automatic palletizer

- Case packer

- Layer palletizer

- Robotic palletizer

- Checkweigher

- Automatic case packer

- Palletizing robot

- Cardboard box/case erector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.