- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

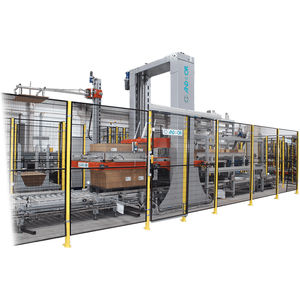

Compact palletizer ETPlayerbottleCartesian

Add to favorites

Compare this product

Characteristics

- Type

- layer

- Product applications

- bottle

- Robot type

- Cartesian

- Sector

- bottling industry

- Other characteristics

- compact

Description

Automatic palletizer with three positions.

• Input area, tray warehouse (up to 10 positions).

• Bottles insertion row by row into tray.

• Palletizing area.

Autonomy of standard machine: a complete pallet.

Type of packaging: Upside trays (1200×800, 600×800, 1200×1000, 600×1000 mm).

Pallet height: Up to 3m.

Advantages:

• It allows handling unsteady bottles because the bottle is not pushed and slide but elevated by the neck and introduced softly into the tray.

• Flexible: adjustable to work with different trays sizes, one or two trays per level.

• It introduces in each tray 1 or 2 rows of bottles more than other automatic systems, optimizing transport costs per bottle.

Optionally:

• Automatic positioning of inverted tray in the last layer of the pallet

• Automatic plastic sheet supply between layers (from roll of film) to protect the bottles neck from touching the cardboard.

• Pallet doser and output pallet accumulation by roller or chain conveyor.

VIDEO

Catalogs

No catalogs are available for this product.

See all of AND & OR‘s catalogsRelated Searches

- Industrial robot

- Wrapping machine

- Bagging machine

- Handling robot

- Automatic bagging machine

- Automatic wrapping machine

- FFS bagging machine

- Strapping machine

- Pallet wrapping machine

- Palletizer

- Automatic strapping machine

- Horizontal bagging machine

- Automatic palletizer

- Case packer

- Layer palletizer

- Robotic palletizer

- Automatic case packer

- Checkweigher

- Palletizing robot

- Cardboard box/case erector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.