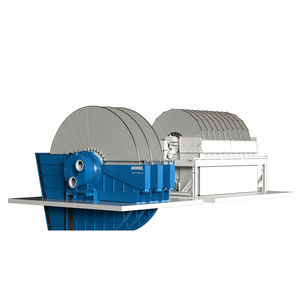

Drum filtration unit CORES™for liquidsautomaticcorrosion-proof

Add to favorites

Compare this product

Characteristics

- Technology

- drum

- Designed for

- for liquids

- Other characteristics

- automatic, corrosion-proof

- Flow

Max.: 2,000 m³/h

(70,629.333 ft³/h)Min.: 100 m³/h

(3,531.467 ft³/h)- Filtration size

Max.: 300 µm

Min.: 1 µm

Description

With the CORESTM vacuum drum filter, ANDRITZ has developed an innovative, long-life solution, and very reliable filter design that offers maximum corrosion resistance.

Advanced design for high reliability

Vacuum drum filters are the state-of-the-art technology for highly corrosive applications such as producing titanium dioxide (TiO2) in sulfuric acid (H2SO4) processes or in processes where slurries with a high content of hydrochloric acid (HCl) are used.

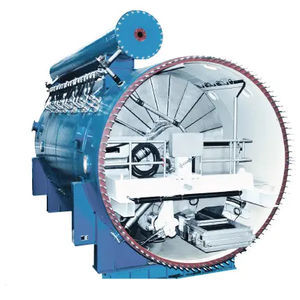

The CORESTM vacuum drum filter is a significant innovation to prevent corrosion. The patented sandwich design provides a permanently chemically resistant surface and can be implemented with different materials to ensure resistance to chemicals. Depending on the size required, the structure itself is made of steel or completely of GRP (glass fiber reinforced plastic).

In addition, all parts in contact with the product are covered with a layer of corrosion resistant, non-reinforced plastic, such as PP, which is commonly used in the chemical industry. Furthermore, some internal wetted parts are made entirely of resistant plastic and are welded together with external surfaces made of plastic to provide a closed surface for corrosive applications.

VIDEO

Catalogs

ANDRITZ METALS presentation

26 Pages

TURBO GENERATORS

12 Pages

Related Searches

- Liquid separator filter

- Pressure separator filter

- Stainless steel separator filter

- Liquids separator

- Water separator filter

- Filtration system

- Eddy current separator

- Process classifier

- Liquid filtration system

- Process separator filter

- High-efficiency pre-filter

- Filter press

- Particulate separator filter

- Decanter centrifuge

- Horizontal decanter

- High-performance pre-filter

- Automatic filter press

- Fine filtration filter

- Separator for the chemical industry

- Vacuum separator filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.