Vacuum dryer GHDbatchmixercompact

Add to favorites

Compare this product

Characteristics

- Technology

- vacuum

- Batch/continuous

- batch

- Associated function

- mixer

- Other characteristics

- compact, high-performance, conical

Description

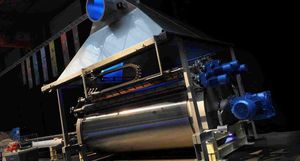

The ANDRITZ batch dryer uses a central, top-driven helical mixer in a conical vessel, enabling smooth and efficient mixing of the dry material. Even sticky products can be processed thanks to the special design of the mixing screw.

Due to its heatable vessel and mixer, the ANDRITZ Gouda helix dryer is a high-performance vacuum contact dryer which is processing the product very gentle at low temperatures. Combining central product discharge and optimized screw design, it guarantees almost residue-free emptying. Thanks to the patented shape, the dryer design is very compact and fits very easily into limited room height. Units are available form 4 liter lab units up to 12 m3 production units. Up to 200 liter dryers, the customer is able to choose stationary or mobile design, which offers a big flexibility and efficiently in production.

The mobile units can be designed with a hinged cover for easy access to the process chamber and 100% inspection of all product wetted parts. Additional equipment is available with interchangeable components such as choppers, vacuum system, heating/cooling system and CIP skid. The dryer can be heated with water, thermal oil or steam, depending on the application. Design pressures and temperature ranges can be chosen according the drying needs of the customer.

Main applications

• Pharmaceuticals / APIs

• Intermediates

• Fine Chemicals

• Fungicides

• Amino acids

• Valuable or toxic metals

• Foodstuff

• Sticky pastes or free flowing powders

Catalogs

No catalogs are available for this product.

See all of ANDRITZ AG‘s catalogsRelated Searches

- Drying system

- In-line dryer

- Drying system for the food industry

- Batch dewatering system

- Centrifugal dewatering system

- Vacuum drying system

- Drying system for the chemical industry

- Drying system with belt conveyor

- Compact drying system

- Fluidized bed dryer

- High-performance dryer

- Rotary drum drying system

- Cooler dryer

- Low temperature dryer

- Bulk material dryer

- Vibrating dewatering system

- Granulator dryer

- Mixer drying system

- Static dryer

- Sludge dewatering system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.