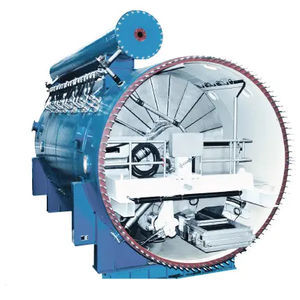

Vacuum filtration unit STARDISCfor liquidsmodular

Add to favorites

Compare this product

Characteristics

- Technology

- vacuum

- Designed for

- for liquids

- Other characteristics

- modular

- Filtration size

Min.: 1 µm

Max.: 800 µm

Description

Flexible design

Smallest footprint

In general, disc filters are the most space-saving solutions in separation. In order to take you to the next level, the STARDISC vacuum disc filters have been engineered to achieve the desired throughput with the smallest possible footprint.

Greatest filter variety

With our modular system, you are able to obtain the filter area best suited for your capacity requirements: You can choose from different diameters and adapt the number of discs used to vary the filter area between 42 and 252 m².

Filter discs in different sizes

Ultra-thin steel filter segments (also in stainless steel) minimize the required system volume. 20 or 30 filter cells reduce the specific volume and enlarge the cake building zone (less dead zones).

Trough options for optimum slurry handling

A common trough with an agitator for highest solids densities as well as a fluid-optimized, self-agitating single trough are at your disposal.

Piping for reliable throughput

Filtrate pipes handle discharge of the filtrate. Depending on the product, two different piping options are available: common piping and individual piping.

Proven technologies

Controlled suspension feeding

The suspension is fed continuously into the trough and flows in the same direction as the rotating filter discs. Each filter disc is divided into filter segments. They rotate at 30-360rph, and approximately 40-52% of the surface area submerges into the suspension. The feed level in the trough is kept constant by weir plate or level regulation.

VIDEO

Catalogs

Related Searches

- Liquid separator filter

- Pressure separator filter

- Stainless steel separator filter

- Liquids separator

- Water separator filter

- Filtration system

- Eddy current separator

- Process classifier

- Liquid filtration system

- Process separator filter

- High-efficiency pre-filter

- Filter press

- Particulate separator filter

- Decanter centrifuge

- Horizontal decanter

- High-performance pre-filter

- Automatic filter press

- Fine filtration filter

- Separator for the chemical industry

- Vacuum separator filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.