- Detection - Measurement

- Flow, Pressure and Level Measurements

- Thermal mass flow meter

- Angst+Pfister Sensors and Power AG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

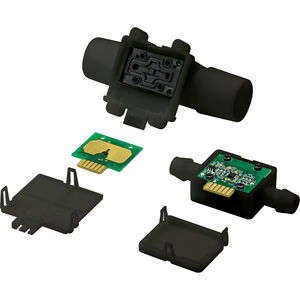

Thermal mass flow meter PFLOW10U-2210for airfor waterin-line

Add to favorites

Compare this product

Characteristics

- Technology

- thermal mass

- Fluid

- for air, for water

- Installation

- in-line

- Applications

- HVAC

- Process temperature

Min.: -25 °C

(-13 °F)Max.: 85 °C

(185 °F)- Process pressure

25 psi

Description

PFLOW: OEM MEMS mass air flow sensors for medical and process control applications

With high resistance towards clogging and pressure shocks

PEWATRON has released the new MEMS mass air flow sensor PFLOW which incorporates the latest MEMS and microelectronics innovations. The PFLOW sensor has a very high resistance towards clogging and pressure shock. Because of the innovative MEMS thermal isolation design does not require fragile thin membranes or surface cavities for thermal insulation. The sensor has a very high sensitivity at low flows and is thus perfectly suited for medical and advanced applications within the process industry.

The flow sensing die consists of two thermopiles symmetrically positioned up and downstream from a heater element which heats up the hot junctions. Each thermopile consists of 20 thermocouples in series to reveal the highest level of sensitivity. When a flow passes over the die, the thermopiles generates an output voltage proportional to the temperature gradient (asymmetric) between the hot and the cold junction due to the Seebeck effect. In case the medium is static (no flow), the temperature profile of both - up and downstream - is symmetric.

Five standard measurement ranges are offered from 0…10 SCCM to 0…2000 SCCM, as well as customer specific ranges between 10 and 2000 SCCM. Accuracy is better than +/-2.0% FS, and the temperature compensated analog output (0…50°C) is highly linear with flow. Analog voltage output is between 1 and 5 VDC, and the sensor is resistant to water condensation. Response time is very fast, and about 1-3 ms.

Catalogs

Other Angst+Pfister Sensors and Power AG products

FLOW SENSORS + LEVEL SENSORS

Related Searches

- Flowmeter

- Liquid flowmeter

- Angst + Pfister pressure transmitter

- Angst + Pfister analog pressure transmitter

- Gas flowmeter

- Pressure switch

- Angst + Pfister pressure sensor

- Angst + Pfister relative pressure transmitter

- Membrane pressure transmitter

- Waterproof pressure transmitter

- Stainless steel pressure transmitter

- Mechanical pressure switch

- In-line flowmeter

- Water flowmeter

- Digital pressure transmitter

- Mass flowmeter

- RS485 flowmeter

- Absolute pressure transmitter

- Angst + Pfister analog pressure sensor

- Threaded pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.