Introduction

The natural gas, prior to pressurization, desulfurization and mixing with aqueous vapor, is passed through a special reformer which is packed

with catalyst for cracking and reforming effluent-a mixture of H2 CO2 and CO.After part heat is recovered, hydrogen will be obtained by converting

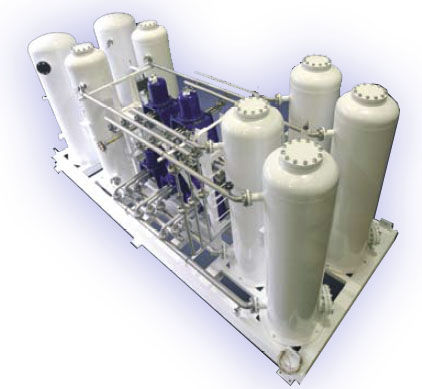

the reforming effluent to reduce the amount of of CO content and the shift gas is purified through PSA to get the pure H2

Specifications

H2 capacity 50-20000 Nm3/h

H2 purity % >99-99.999%

Work pressure 1.3-2.0MPa

Technical Features

-Safe and reliable operation

-High automation

-Low operational cost means your investment is recovered in a short period of time

-The desorbed gas from PSA can be burned; which can both reduce the fuel consumption and decrease the ventilation of the waste gas.