- Production Machines

- Machine for the electronics industry

- Pulsed magnetron

- Angstrom Sciences, Inc.

Pulsed magnetron HiPIMScylindricalcircular

Add to favorites

Compare this product

Characteristics

- Options

- pulsed, cylindrical, circular

Description

High Power Impulse Magnetron Sputtering or HiPIMS is a relatively recent advance in pulsed sputtering technology using very high energy, short duration pulses to generate a plasma discharge that ionizes a large percentage of the sputtered atoms. The ionized flux can then be guided for increased control of the coating properties.

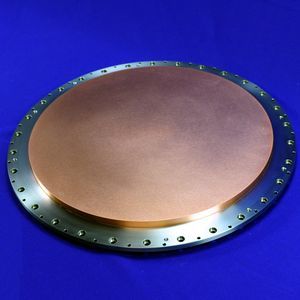

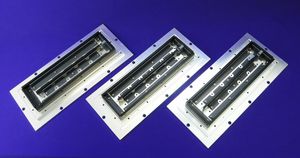

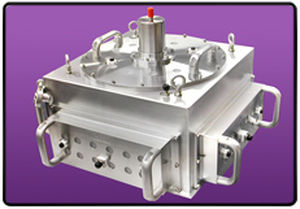

Angstrom Sciences has developed a series of sputtering cathodes capable of sustaining these extreme power densities of greater than 1500 Watts/in2 for continuous long running production applications. Along with our patented turbulent target cooling, Angstrom Sciences’ high impulse power pulsed magnetron sputtering cathodes incorporate additional cooling channels in the anode body and mounting flanges to maintain optimum cooling during process operation.

Other features include passive and active magnet arrays that keep the field intensity at the target surface consistent through target life which is critical in the HIPIMS process for both the reduction of arcing and optimum ionization of the sputtered material.

These features along with solid anode construction allow for consistent repeatable performance in demanding applications like HiPIMS or any high-power long run time applications.

HiPIMS magnetrons are directly cooled and available in circular, linear and cylindrical designs.

Catalogs

No catalogs are available for this product.

See all of Angstrom Sciences, Inc.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.