- Packing - Handling - Logistics

- Packing and Packaging

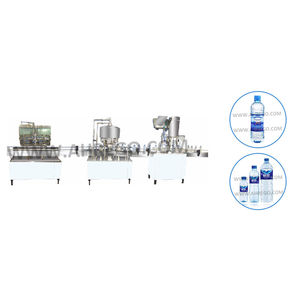

- Plastic bottle rinser / filler / capper

- Anhui Koyo Rego Machinery Technology Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Beverage rinser / filler / capper RGH 24-24-8 for plastic bottlesautomatic

Add to favorites

Compare this product

Characteristics

- Product applications

- beverage, for plastic bottles

- Specifications

- automatic

Description

The machine is mainly applied for the filling of beverage. Integrating with washing, filling and sealing, it has temperature control device for heat filling and realizes full automation in the whole process, suitable for polyester bottle and plastic bottle filling of juice and tea. The bottle types applicable for various parts are easily, conveniently and rapidly adjustable. It adopts new micro-negative pressure filling, stable and reliable. Compared with the machines of the same specification, the benefit of the machine is larger.

The machine adopts advanced Mitsubishi programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectrical inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

Washing Workstation - 24

Filling Workstation - 24

Capping Workstation - 8

Production Capacity - 6,500B/H (500ml)

Machine Power - 4kw

Machine Weight - 6500Kg

External Dimensions (L*W*H) - 3,100 (mm)* 2,450 (mm) *2,800 (mm)

Other Anhui Koyo Rego Machinery Technology Co., Ltd. products

Bottle blowing filling equipment

Related Searches

- Packing machine

- Automatic packing machine

- Bagging machine

- Automatic labelling machine

- Filler for the food industry

- Automatic bagging machine

- Packing machine for the food industry

- Vertical bagging machine

- Bulk material bagging machine

- Bottle labeling machine

- Bagging machine for the food industry

- Shrink wrapper

- Semi-automatic filler

- Automatic sleeve wrapping machine

- Filling system for the chemical industry

- Packaging machine for the food industry

- Granulate bagging machine

- Powder bagging machine

- Bag filler

- Weight filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.