- Production Machines

- Cutting Machine

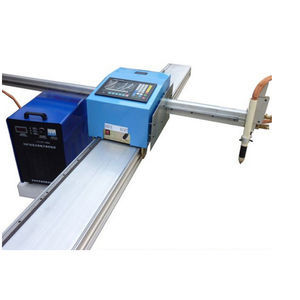

- Plasma cutting machine

- Anhui Runbang Heavy Industry Machinery CO., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Plasma cutting machine RB L-3060for aluminumfor steelfor stainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- plasma

- Material

- for aluminum, for stainless steel, for steel, for copper

- Product handled

- sheet metal

- Configuration

- gantry type

- Other characteristics

- high-precision, linear

- Cutting speed

Min.: 50 mm/min

(0.033 in/s)Max.: 3,500 mm/min

(2.297 in/s)- Overall length

3,400 mm

(134 in)- Overall width

6,000 mm

(236 in)- Height

2,500 mm

(98 in)- Weight

850 kg

(1,873.93 lb)

Description

1.This cutting machine is widely used in cutting sheet metal to various size and shape.

2.This cutting machine adopts gantry type structure,double driving and linear guide,plasma cutting

3.Torch number is set according to customer' request. Cutting plate is normally 1-60mm thick.

Gantry structure double driving increase the work stability and accuracy; double lifting devices makes operation simple and smoother.

4.The whole wedding thick square steel tube with artificial aging processing frame.

Reasonable working table design, covered with finishing cating iron mask to protect the vertical steel plate.

5.Reasonable slope design to ensure the processed workpiece

Adopted with Japanese Panasonic motor servo driver and Taiwan made high-precision servo gear,rack and pinio to ensure low noise, steady and precision performance.

6.Adopted with US made control system with Germany auto-saving material auto-layout software.

Equipped with HYPERMAX powermax series cutter machine and US original torch.

7.Applications:Metal parts cutting, thick abnormal metal plate cutting and welding processing.

All kinds of metal materials such as steel, copper, aluminum and stainless steel can be processed.

Catalogs

No catalogs are available for this product.

See all of Anhui Runbang Heavy Industry Machinery CO., Ltd.‘s catalogsOther Anhui Runbang Heavy Industry Machinery CO., Ltd. products

Plasma Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Metal fabrication cutting system

- Compact cutting system

- Steel cutting system

- Bridge cutting system

- Carbon steel cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.