- Metrology - Laboratory

- Inspection and Monitoring

- Corrosion monitoring system

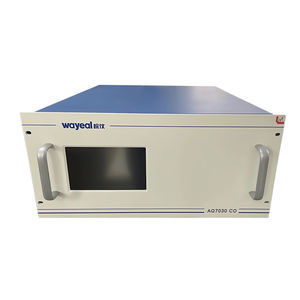

- AnHui Wanyi Science and Technology Co., Ltd.

Pressure monitoring system CEMS1300humidityconcentrationflow

Add to favorites

Compare this product

Characteristics

- Type

- pressure, humidity, concentration, flow, corrosion, CO2, O2, NOx, CO

- Applications

- measurement, gas, water, environmental, particle

- Domain

- for the automotive industry, for the construction industry, for the electronics industry, for medical applications, for the petrochemical industry, for the chemical industry, for the food industry, for the metallurgical industry

- Technology

- FTIR, electrochemical

- Configuration

- floor-standing

- Other characteristics

- real-time, continuous, online, automatic, data acquisition

Description

CEMS 1000 system is composed of a gaseous pollutant monitoring subsystem, a particulate monitoring subsystem, a flue gas parameter monitoring subsystem and a data acquisition and processing subsystem. It can continuously monitor the concentration, flow rate, pressure, humidity and other multiple relevant parameters of SO2, NOx, O2, CO, CO2, HCI and soot (particulate), statistical emission rate, total emission, etc., and can effectively manage the measured data. Moreover, it has such functions as real-time transmission of on-site data, remote fault diagnosis, report statistics and graphic data analysis, and can realize unattendance on the work site.

Performance characteristics

High reliability

The gas analyzer is equipped with the light source of pulsed xenon lamps, of which the life span is up to 10 years; It is equipped with grating spectroscopy and array sensors and has no moving parts.

With the integrated design, the dust monitor has a compact structure.

High measurement accuracy

The condensation method is adopted to measure SO2 and NOx to avoid inaccurate measurement due to the absorption of SO2 by condensed water and the corrosion of the instrument caused by the formation of sulfurous acid;

Differential absorption spectroscopy technology (DOAS) is adopted in SO2 and NOx analysis, which effectively solves the influence of water, dust and other factors on measurement accuracy;

the principle of in-situ laser backward scattering is adopted for the dust meter, so that it has high testing sensitivity, fast response speed, built-in self-calibration function, accurate measurement and good stability.

Easy maintenance and low maintenance cost

Catalogs

No catalogs are available for this product.

See all of AnHui Wanyi Science and Technology Co., Ltd.‘s catalogsOther AnHui Wanyi Science and Technology Co., Ltd. products

Environmental monitoring instrument

Related Searches

- Measurement monitoring device

- Real-time monitoring device

- Temperature monitoring device

- Environmental monitoring device

- Continuous monitoring device

- Digital monitoring device

- Condition monitoring device

- Process monitoring device

- Online monitoring device

- Benchtop monitoring system

- Ethernet monitoring device

- Alarm monitoring device

- Automatic monitoring device

- Compact monitoring device

- Gas monitoring device

- Data acquisition monitoring device

- Chemical monitoring system

- Concentration monitoring device

- RS-485 monitoring device

- Pressure monitoring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.