- Production Machines

- Forming Machine

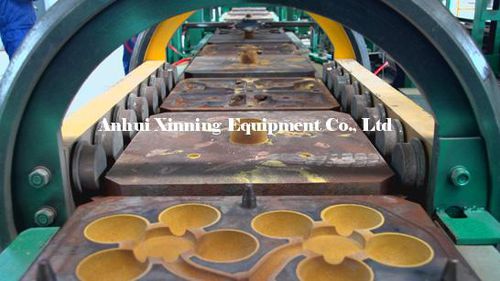

- Hot forming machine

- Anhui Xinning Equipment Company

Hot forming machine for metalmetalautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- hot

- Product handled

- for metal

- Treated material

- metal

- Operating mode

- automatic

Description

Riser is an indispensable technology in the smelting forging. Up to now, in smelting forging industry, riser forming and moulding still requires heavy workload and also needs to be pre-forged and stored in advance. It asks for input of special equipment and has high manufacturing cost; when the risers are needed, they have to be installed one by one. Especially, in the moving and installing process, the riser is easy to be damaged; when installing, there are clearance between the riser and moulding cavity, which is difficult to clean, especially, when it is of metal coated sand forging; and it is also apt to form lots of loose sand, which requires cleaning in time. The cleaning takes lots of time and effort, what’s more, if the loose sand is cleaned incompletely, the remnant will be brought by the metal fluid into casting system during casting process, as a result, it will directly influence the quality of casting product.

Equipped with the patented technology, ZL201310278166.5 etc, riser and moulding cavity are integrated so as to achieve the one-stop moulding. It does not only avoid transportation and installation to implement production and moulding synchronically and get rid of loose sand formed in the riser installation, but also saves the input of core shooter.

A Integration of riser and moulding cavity improves the quality of coated sand moulding to ensure the internal quality of castings;

B Integration of riser and moulding cavity saves installation and separate production in the coated sand moulding process, thus, avoiding special equipment input and saving labor force;

Catalogs

No catalogs are available for this product.

See all of Anhui Xinning Equipment Company‘s catalogsOther Anhui Xinning Equipment Company products

Casting Line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.