- Production Machines

- Plastics Processing

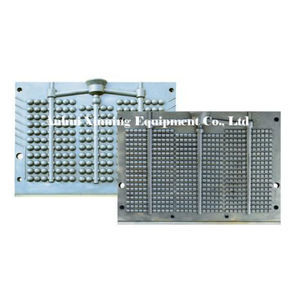

- Standard mold base

- Anhui Xinning Equipment Company

Standard mold base

Add to favorites

Compare this product

Characteristics

- Other characteristics

- standard

Description

Made of special metal materials, the mould is used to produce balls with the chilling forming technology. The surface of the product is smooth, slick and the grains on which are evenly distributed. Its rigidity is significantly improved and the core and surface are basically of the same rigidity, thus, enhancing its comprehensive physical performance and abrasion-resistant performance. The mould is easy to be operated. In addition, it is replaceable between the mould of the same specifications, therefore, if the ball core of the assembling mould is worn, it can be replace, usually for 5~10 times. After the ball core is changed, the operational effect of the mould is as good as the new one, thus, greatly reducing the use cost of mould.

Products made by this series of mould have the following attributes: the product is free from distortion, forging defects and has high melted iron use efficiency, high technological yield and long service life. Optimization and upgrading can thoroughly solve the exhaust problems in the operational process to avoid the occurrence of such phenomena as slippage and cold shut etc. Up to now, it is the best replacement of single mould, disposable mould and sand forging mould.

Catalogs

No catalogs are available for this product.

See all of Anhui Xinning Equipment Company‘s catalogsOther Anhui Xinning Equipment Company products

Ball&Cylpebs Mould

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.