- Materials - Tools - Components

- Standard Mechanical Component

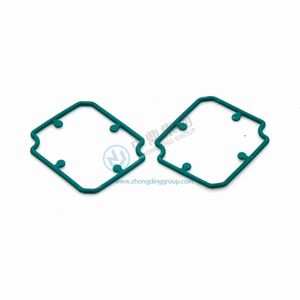

- Spring mechanical seal

- ANHUI ZHONGDING SEALING PARTS CO.,LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

Spring mechanical seal pumpchemicaldry

Add to favorites

Compare this product

Characteristics

- Type

- spring

- Applications

- pump

- Domain

- chemical

- Other characteristics

- dry

Description

mechanical seal for automotive engine cooling water pump, referred to as water seal, mainly composed of two parts: rotating ring and static ring. Static ring is installed in the pump shell, it is in static state in the actual use; dynamic ring is installed in bearing, it revolves with the bearing together in the actual use. The dynamic sealing medium is a pair of friction rings (dynamic ring, static ring), it preloads the sealing end through the bottom spring and provide axial pressure compensation.

KACO, which first developed water seal with Opel in 1942 and patented, is the world's first water seal manufacturer. Products can be divided into the following categories according to specifications: CS2 (12 axis), TS15 (15 axis), TS16 (16 axis), TS19 (19 axis) and lip seal. Products can be divided into: standard, anti-high pressure and anti-dry type according to function. The main indicators of water seal: working height, rotating ring end beating, friction flatness and roughness and axial load (spring axial elastic force). Factors affecting the life of the water seal are: temperature, pressure, rotational speed, time, dynamics, and the physical and chemical aspects of the coolants. KACO recommends using organic acid coolants.

water pump seal for commercial vehicles,passenger cars andmechanical mechinery,electronic pump seal for new energy battery cooling.

Other ANHUI ZHONGDING SEALING PARTS CO.,LTD products

Sealing Products

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.