Spray dryer for the food industrygasfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Technology

- spray

- Applications

- for the food industry, for the pharmaceutical industry, for the chemical industry, gas, air

Description

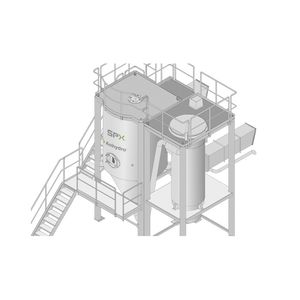

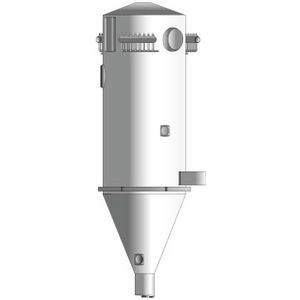

The Spray Bed dryers are used in the food, chemical and pharmaceutical industries to produce dust-free, agglomerated, dispersible and free-flowing powders. Our Spray Bed dryers are available in designs that are tailored to each of these industries.

FEATURES

Spray Bed Dryers - Function and Principle of Operation

The drying process involves product being atomized as a fine spray, which mixes with recycled fines and the fines elutriated from the integral fluid bed. The primary air flow enters at the top of the chamber; the secondary air flow enters through the fluid bed where second stage drying occurs.

The agglomerated products falling into the bed are dried to the correct moisture content before being discharged from the chamber.

To optimize the control of particle size, the product caught in the spent drying air is separated out in the cyclone or textile filter and returned to the atomization zone in the drying chamber. The degree of agglomeration and particle size is influenced by operating conditions, which alter residual moisture level of particles within the atomization zone. A wide range of particle sizes can be formed. Both soluble and insoluble products can be agglomerated in this process.

Capacity Profile

From 5 kg/h to 10 t/h

Designs Available

Open cycle systems applying atmospheric drying air

Closed cycle systems, either as low-Ox or inert gas (nitrogen)

Advantages

High thermal efficiency

Improved control over particle size distribution

Minimum of fines

Straightforward CIP

Customized to individual requirements

Proven reliability and high availability

Long service life

Traceability

Catalogs

No catalogs are available for this product.

See all of Anhydro‘s catalogsRelated Searches

- Drying system

- In-line dryer

- Air blast drying system

- Drying system for the food industry

- Batch dewatering system

- Hot air drying system

- Drying system for the chemical industry

- Dryer for the pharmaceutical industry

- Air drying system

- Plastic dewatering system

- Dry air drying system

- Coating dryer

- Spray drying system

- Modular drying system

- Gas dryer

- Cylindrical drying system

- Nozzle dryer

- Conical dryer

- Cylinder drying system

- Pilot dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.