- Production Machines

- Forming Machine

- Compression press

- Anistek Mechatronic

Compact press MONO500compressionautomatichigh-speed

Add to favorites

Compare this product

Characteristics

- Function

- compression

- Structure

- compact

- Control

- automatic

- Other characteristics

- high-speed

- Applications

- for production

- Rate (strokes/min)

120 p/min

Description

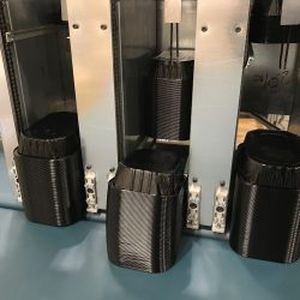

The latest in Anistek Mechatronic family, the servo press “compact” MONO500. It ‘was designed to meet the market demand to increase competitiveness by reducing

investment costs (-70%), the cost of production and maintenance. The new concept of “all in one”, where in only 2.5 x 0.8 x 2.5 m are enclosed in the uncoiler, the servo press, the scrap collection system and the stacking unit. The MONO 500 comes at an operating cycle equal to 120 strokes per minute and allows the production of aluminium trays with cut imprinting up to 500 x 500 mm.

With this servo press, the concept of adjustment resulted the maximum level currently available. The machine recognizes the type of mould inserted and adapts all

the working parameters. In addition, record the historical work of the machine and the single moulds used. This, combined with the integrated remote control system and to the integrated video system (optional) allows you to reach the best production cycle with reduction of

maintenance costs (programmed) and any downtime and unproductive periods.

Catalogs

MONO500

12 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.