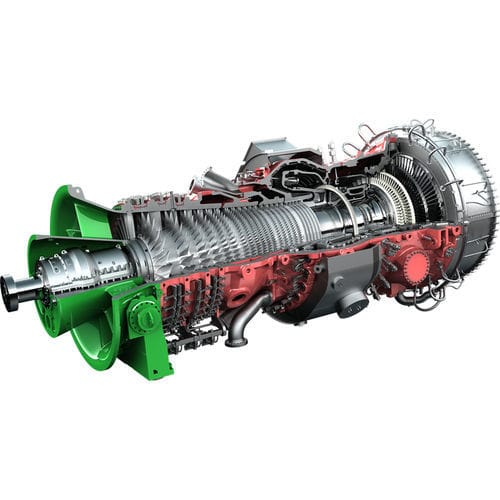

Gas turbine GT26for power generationcombined-cyclehorizontal shaft

Add to favorites

Compare this product

Characteristics

- Type

- gas

- Applications

- for power generation

- Other characteristics

- combined-cycle, horizontal shaft

- Rated power kW

370,000 kW, 540,000 kW, 1,083,000 kW

(503,059.83 hp, 734,195.42 hp, 1,472,469.71 hp)- Efficiency

41 %, 61 %, 61.2 %

Description

For the GT26 turbines, Ansaldo Energia has developed its exclusive sequential combustion technology – also adopted by the GT36 – which provides exceptional Combined Cycle performance over a wide load range and exceeds 61% net efficiency at full load.

Additional features include the ability to partially or fully shut down the second combustor in the event of low power demand – so enabling unprecendented minimum environmental load operation.

A wide range of fuel variations, that include the use of hydrogen, is possible without hardware changes.

The welded rotor means no de-stating and no disk replacement, thus benefitizing Customers with reduced maintenance costs.

The outstanding reliability of the GT26 is confirmed by >3.4 million fired hours and >44,000 starts on a worldwide fleet of +100 units.

Environmentally sustainable

NOx level down to 15 ppm in dry gas mode.

High Hydrogen Capability

Due to the high burning velocity and high flame temperature, standard gas turbine combustion technology struggles at high hydrogen content with high NOx emissions and the risk of flashback.

This usually results in the need to derate power in order to comply with required standards.

Based on two successive combustion stages, the GT26 recovers the derating of the first stage by shifting the fuel into the second stage. This allows for full operational flexibility, low NOx and no derating.

The GT26 engine represents a future-proof investment, keeping its high efficiency at high hydrogen contents. Currently 45% hydrogen in natural gas blends are released for operation, providing best-in-class hydrogen capability.

Catalogs

No catalogs are available for this product.

See all of ANSALDO ENERGIA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.