- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Simulation software Additive Printanalysisthermal analysismachine

Add to favorites

Compare this product

Characteristics

- Function

- analysis, thermal analysis, simulation

- Applications

- machine

- Type

- 3D, 2D

Description

Save Time and Build Accurate Parts With Ansys Additive Print

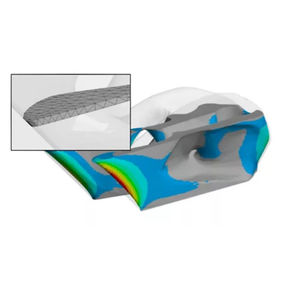

Build parts right the first time with Additive Print. Users can check for distortion, stress and strain regions, predict blade crash and export to Ansys Workbench Additive for advanced post processing analysis. Different level of simulation fidelity allows users to go from quick estimation to detailed thermal analysis.

Powder Bed Fusion

Predict Stress and Thermal Strains

Auto Distortion Compensation

Predict Blade Crash

Quick Specs

Eliminate the guesswork with Ansys Additive Print. Get insight into how parts will behave during a build and takes corrective steps to get the parts right the first time.

Import STL from any Software

Read Machine Build Files

Simulate Thin-Walled Structures

Predict Distortion During Builds

Predict Distortions

Predict Stress and Thermal Strains

Automatic Distortion

Predict Residual Stresses

Predict Potential Blade Crash

Layer-by-Layer Visualization

Perform Thermal Analysis

Transfer Files to Workbench

Material Tuning Wizards

Auto Distortion Compensation

Predict Blade Crash

Eliminate the Guesswork in Metal Additive Manufacturing Workflows

Additive Print helps users eliminate guesswork and hours of wasted time in metal Additive Manufacturing workflows. The easy-to-use yet powerful standalone solution is essential for operators and designers looking to save time and build quality parts.

Additive Print uploads supports generated by other software tools with additional materials (Al357, AlSI10Mg and more) available for high-fidelity thermal simulations.

Catalogs

No catalogs are available for this product.

See all of ANSYS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- ANSYS automation software

- ANSYS management software

- ANSYS analysis software

- ANSYS process software

- ANSYS CAD software

- ANSYS control software

- Real-time software solution

- Online software

- ANSYS design software

- ANSYS 3D software

- Monitoring software solution

- Measurement software

- Interface software

- ANSYS industrial software

- ANSYS quality software

- ANSYS simulation software

- Visualization software solution

- ANSYS automated software

- ANSYS development software

- Network software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.