It is mainly used for surface sandblasting, removing rust, decontamination of shipyards, bridges, chemical industry, containers, water conservancy, machinery, pipeline equipment, and spare parts.

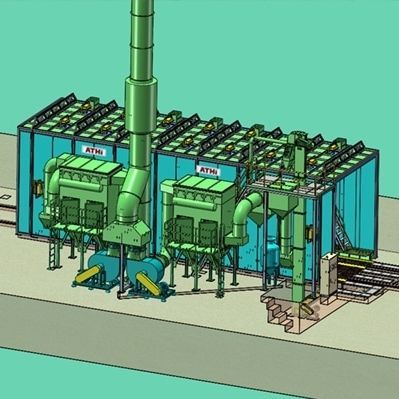

This series of sandblasting rooms are mainly suitable for cleaning the surface and inner cavity of large-scale structural parts, box-type castings, large-scale castings, etc. The projectile relies on compressed air as a power source, is accelerated by the shot blaster, and then sprayed on the surface of the workpiece.

It adopts a new scraper-type pill feeding structure. The pit of the equipment is shallow, which can reduce the foundation cost by 70-80%. Indoor transmission failure is more diminutive. Maintenance is simple, stable, and reliable. The scraper conveyor is divided into two types: cylinder drive and motor drive, to meet the needs of different factory conditions.

The continuous and double gunshot blasting system can significantly improve the cleaning efficiency; the gun sandblasting and air-jet switch use wireless remote control, with stable frequency, high feasibility, a control distance of 100 meters, low power consumption, and high sensitivity.

A high wear-resistant rubber plate protects the chamber body, which is impact resistant and easy to replace.

The environmental protection high-pulse filter cartridge dust collector is adopted, and the dust removal efficiency can reach 99.5%.

Thirty years of production and design experience in sandblasting.

Equipment gets the international certification: CE, ISO14001, ISO9001, TUV, BV.

Get a government-granted endorsement of trust. ATHI is trustworthy.

All designs adopt 3D Design.