- Industrial machines and equipment

- Surface Treatment Equipment

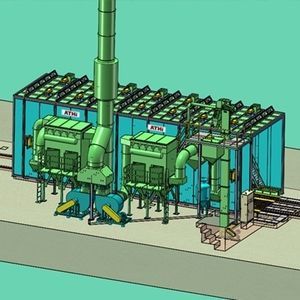

- Automatic sandblasting machine

- Antai Heavy Industry Machinery Co., Ltd.

Automatic sandblaster AT300

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

Description

Widely used for descaling, surface texturing, and paint preparation, mainly used to clean rust removing at the oil field, container renewal, etc. Pneumatically generated abrasive recovery system makes it used without dust and disposal problems. Vacuum Blasting is ideal for big objects such as ship hulls, large tanks, and concrete bridge surfaces.

The portable system is used for lead and asbestos abatement, indoor blasting, bridge and road maintenance, building restoration, and other steel and concrete cleaning applications.

The flexible system can blast and recover simultaneously or independently.

The automatic pulse jet prevents the clogging of dust filters. Dust is captured in a container for easy disposal.

Quick opening hatches make cartridges and filters easy to remove and replace.

Moisture separator and media vibrator ensure even flow of abrasive.

100% dust-free operation because of fully automated blasting & vacuum start/stop sequence.

Wheels and casters offer ease in mobility. The equipment can be relocated or transported easily.

A wide range of brushes fit all surfaces such as flat, cornered, and radiused.

Thirty years of production and design experience in sand blasting.

Equipment gets the international certification: CE, ISO14001, ISO9001, TUV, BV.

Get a government-granted endorsement of trust. ATHI is trustworthy.

All designs adopt 3D Design.

OEM&ODM factory, High-quality after-sales service.

The equipment is environmentally friendly, safe, and cost-effective.

All adopt general parts, easy to buy and replace.

Exported to more than 80 countries and regions in the world

Domestic certificate: AAA corporate certificate (The first AAA enterprise in Qingdao).

Catalogs

No catalogs are available for this product.

See all of Antai Heavy Industry Machinery Co., Ltd.‘s catalogsOther Antai Heavy Industry Machinery Co., Ltd. products

PRODUCTS

Related Searches

- Blast machine

- Metal shot blasting machine

- Spray booth

- Blast room

- Sandblaster

- Pressure sandblaster

- Filter spray booth

- Enclosed spray booth

- Vehicle spray booth

- Continuous shot blasting machine

- Turbine shot blasting machine

- Automatic sandblaster

- Hook shot blasting machine

- Automatic blast room

- Roller conveyor blast machine

- Compact blast machine

- Manual spray booth

- Conveyor blast room

- Paint booth for the chemical industry

- Double blast cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.