- Production Machines

- Textile machinery

- In-line liner production line

- Antai Heavy Industry Machinery Co., Ltd.

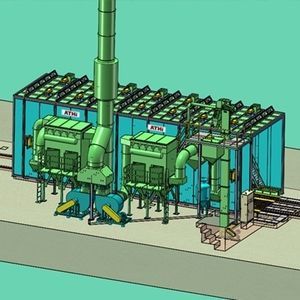

In-line liner production line QGW20-50

Add to favorites

Compare this product

Characteristics

- Options

- in-line

Description

3PE anti-corrosion coating is suitable for pipeline protection with complex terrain and severe corrosion. The equipment is mainly used for oil, water, natural gas, and other steel pipelines.

Durable lifetime: 3PE epoxy coated steel pipe has good stability and anti-aging performances under average work temperature and pressure conditions; consequently, its lifetime can prolong above 50 years.

Corrosion resistance: Due to PE elements, structure stability is very high. It is resistant to corrosion of natural gas, liquefied petroleum gas, artificial gas, and other chemical subjects, with no need for secondary anti-corrosion equipment. The chemical of soil does not produce any effects on the pipe.

Flexibility: 3PE is a soft and flexible material. It can prolong five times the length and then break. At the same time, it is easy to bend and has no damage. 3PE coating steel pipe can bypass objects and cut the fees of installation.

Good resistance to impact and earthquake: Polyethylene is not fragile under low temperatures. Therefore, it is safely used in the temperature range of -60℃~60℃. So it can adapt to going down of pipeline, Work in winter. Due to good impact performances, the PE pipeline won’t easily break.

Catalogs

No catalogs are available for this product.

See all of Antai Heavy Industry Machinery Co., Ltd.‘s catalogsOther Antai Heavy Industry Machinery Co., Ltd. products

PRODUCTS

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.