- Products

- Automatic core shooting machine

- Antai Heavy Industry Machinery Co., Ltd.

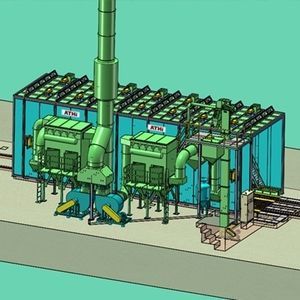

Automatic core shooting machine Z955(SG) series

Add to favorites

Compare this product

Characteristics

- Type

- automatic

Description

It is a hot box core shooting machine widely used in the foundry casting industry. Double working station design adopts vertical type with double active moulds and single fixed moulds. Two different sets of moulds can be installed. It’s suitable for casting small and medium-sized casting cores such as automobiles, valves, and machine tools. It is ideal for casting enterprises to improve product quality and production efficiency.

It is suitable for vertical parting type moulds. It can produce shell core or solid core by heating phenolic resin-coated sand with high efficiency, less sand, and less gas.

PLC program control, LCD screen parameter setting, process display, fault diagnosis.

Manual/automatic / jog control, automatic digital display temperature control.

Two kinds of control programs respectively produce shell core or solid core. The template is flipped by 180°±30°, emptying the residual sand to produce the shell core, and it can be used as a solid core if it can’t reverse.

High-frequency quenching rigid chrome guide rail has a long service life—a hydraulic buffer of the rotary cylinder, smooth reverse and no vibration, and no-wrap around the rotating ring.

The way of taking cores out is to take them out by opening moulds, the active template is forked at 90° to eject cores, pick up seats by flat trolley, and upturn at 90° to pick up sand cores.

The core shooting machines have two types: single and double working stations. The Z956SG dual working station model can simultaneously complete two sets of moulds and mould lateral pumping function.

The driving method is pneumatic, hydraulic, and pneumatic-hydraulic combined driving.

Catalogs

No catalogs are available for this product.

See all of Antai Heavy Industry Machinery Co., Ltd.‘s catalogsOther Antai Heavy Industry Machinery Co., Ltd. products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.