Air heater steamcustomstainless steel

Add to favorites

Compare this product

Characteristics

- Treated product

- air

- Heat source

- steam

- Other characteristics

- stainless steel, high-temperature, high-pressure, custom, low-pressure, for the food industry, for the chemical industry, for pharmaceutical applications

- Power

Min.: 0 kW

(0 hp)Max.: 10,000 kW

(13,596 hp)- Temperature

Min.: 80 °C

(176 °F)Max.: 300 °C

(572 °F)- Pressure

Min.: 0 bar

(0 psi)Max.: 70 bar

(1,015.3 psi)

Description

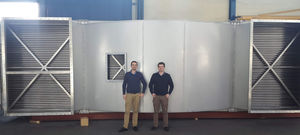

Finned tube heat exchanger type using steam to heat up gaseous media (e.g. air), also called steam air heaters, steam heat exchangers or steam coil air heaters

Customized according to client specification and request (e.g. equippable with air pre-heater recuperator or with optional electrical or oil heater to reach higher temperatures)

Insulated housing (fully welded, sanitary design) and extractable elements

Condensate cooling and innovative safety system (see below)

Selected Project References

Exemplary Steam Heat Exchanger Unit with Condensate Cooling and Safety System

Condensate Cooling

Use of flash steam and condensate of the steam coils to pre-heat the process air

Separate flash steam and separate condensate stage, for stable running conditions at different capacities

Returning of water without any flash steam to the tank

Materials And Characteristic Values

Housing: Stainless steel (AISI 304 or AISI 316) with mineral wool insulation

Finned tubes: Stainless steel (AISI 304 or AISI 316)

Fins: Aluminum or stainless steel

Air volume: up to 150’000 kg/h per device

Discharge temperature: 80 to over 200 °C, depending on steam pressure, or more than 300°C with optional electrical or oil heater

Steam pressure: up to 70 bar

Safety System

Innovative and field-proven system consisting of pressure sensors, valves and bypass piping

To avoid steam hammers which caused a quite long history of damage at steam heat exchanger units without safety system

Steam hammers occur when the heater coils fill up with water especially during low capacity cases

Related Searches

- Heat exchanger unit

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Heater

- Tubular heat exchanger

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Gas heater

- Industrial heat exchanger unit

- Recovery unit

- Air heater

- Compact heat exchanger unit

- Electric heater

- Shell and tube heat exchanger

- Gas/gas heat exchanger

- Heat exchanger for the food industry

- Energy recovery system

- Stainless steel heater

- Heat recuperator

- Steel heat exchanger unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.