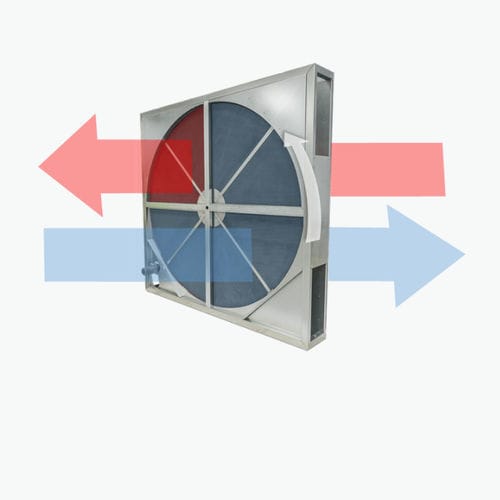

Regeneration Air Outlet:

The regeneration air in couterflow dries out and therefore «regenerates» the sorption wheel

Process Air Inlet:

Up to 200’000 kg/h

Usually flows through 180° up to 270° sector (as shown) of the sorption wheel

Regeneration Air Inlet:

Temperatures in the range 120-170°C

Usually flows through 90° (as shown) up to 180° sector of the sorption wheel

Process Air Outlet:

Can be dried down to below 2 g/kg humidity without condensation

Main Features

Unit to dehumidify process air without condensation

Making use of the adsorption process defined as the accumulation of molecules on a surface

Core part is the so called sorption (or dessicant) wheel which accumulates (adsorbs) the water dissolved in the process air on its surface

Many additional components can be included in the sorption units (see optional equipment) according to the client specification and request

Materials And Characteristic Values

Sorption wheel (also known as desiccant wheel): silica gel

Rotation: maintenance-friendly chain drive with a constant speed of around 10 to 15 rotations per hour

Seals: radial and axial seals (as shown on the right) to separate the two counter flows from each other and from the surroundings

Housing: Stainless steel with mineral wool insulation

Optional equipment

Regeneration air heater (e.g. steam)

Pre-cooler (condensation dehumidifier) for higher drying capacity

Air cooler after the sorption wheel (as the air gets heated up by the drying process)

Heat recovery systems

Sound attenuators

Filter stages for both process and/or regeneration air