Automatic filling machine bottlefor food productsfor hazardous materials

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- bottle

- Product applications

- for food products, for hazardous materials, for corrosive products

- Domain

- for the chemical industry, for the pharmaceutical industry, for the cosmetics industry

- Type

- gravity, linear

- Number of heads

- multi-head

- Other characteristics

- intermittent-motion

Description

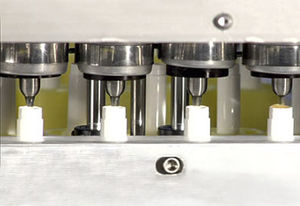

The Automatic Gravity Filler is ideal for filling thin liquids with consistent viscosity. Volumetric time gravity filling method produces repeatable and accurate fill volumes. The Gravity Filler is manufactured with a heavy duty 304 stainless steel, tig-welded tube frame and reservoir. It also features user friendly PLC controls and touch screen HMI panel. This filler is capable of accommodating up to 16 heads, and utilizes an automatic product level sensing float system for filling efficiency. Many more features and options are available for even more versatility and customization. Gravity Fillers are utilized by the food and beverage, cleaning and specialty chemical, pharmaceutical, cosmetic and personal care industries for various filling projects. The Automatic Gravity Filler can be built to suit a wide variety of applications including sanitary, hazardous, flammable, and corrosive products and environments.

Features

Standard Construction: Heavy duty 304SS free-standing frame

Number of Fill Heads: 1 to 16

Reservoir: 304SS tank is standard

Filling Size: 0.5oz to 5gal

Power Requirement: 115VAC, single phase, 20 amp, 50-60Hz

Air Requirement: 3-6CFM @ 90PSI clean, dry, compressed air

Dimensions & Weight: Subject to model configuration 04SS fill head bar

User friendly PLC controls with touch screen HMI

1/100th second individual fill head control 316SS drain valve with Teflon seals

Matching throttle valve for each fill head valve

Pneumatic Indexing Gates (entry and exit)

VIDEO

Catalogs

No catalogs are available for this product.

See all of APACKS‘s catalogsRelated Searches

- Automatic filler

- Wrapping machine

- Liquid filler

- Automatic labelling machine

- Automatic wrapping machine

- Stretch film wrapping machine

- Bottle filler

- Food product filling machine

- Palletizer

- Bottle labeling machine

- Volumetric filler

- Shrink wrapper

- Semi-automatic filler

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Multi-head filler

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeller for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.