Automatic filling machine bottlefor liquidsfor the cosmetics industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- bottle

- Product applications

- for liquids

- Domain

- for the cosmetics industry

- Type

- pressure, linear

- Number of heads

- multi-head

- Other characteristics

- overflow, intermittent-motion

- Volume

Max.: 18,927 ml

(640 US fl oz)Min.: 29.5 ml

(1 US fl oz)

Description

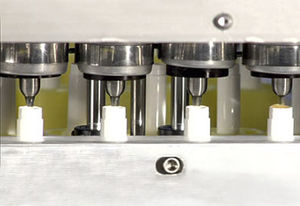

APACKS Automatic Pressure Overflow Filler is typically used in consumer packaging applications where a consistent visual (cosmetic) fill level is required. The desired product to be filled is held in a stainless steel reservoir, then pumped into a manifold to disperse product to each of your filling nozzles. Once the product reaches your desired cosmetic fill level in each bottle, excess product or foam overflows back to the reservoir. Advantages of the Overflow Filler include even fill levels, variable pressure pump speed control (to reduce foam), and ease of operation.

Features

This Filler is manufactured with heavy duty 304 stainless steel, high quality tig-welded tube frame and is available with 1 to 16 Fill Heads. It also comes standard with PLC controls and color touch screen HMI, a stainless steel reservoir, and Pneumatic Indexing Gates, plus many more features. Further options are available for even more versatility. Overflow Fillers are commonly used for filling beverages and other thin products, especially where foam or bottle inconsistency might be an issue. APACKS’ Overflow Filler can be built to suit sanitary, hazardous, flammable and corrosive environments.

Standard Construction: Heavy duty 304SS, tig-welded tube frame

Number of Fill Heads: 1 to 16

Reservoir: 304SS tank is standard

Filling Size: 1oz to 5gal

VIDEO

Catalogs

No catalogs are available for this product.

See all of APACKS‘s catalogsRelated Searches

- Automatic filler

- Wrapping machine

- Liquid filler

- Automatic labelling machine

- Automatic wrapping machine

- Stretch film wrapping machine

- Bottle filler

- Food product filling machine

- Palletizer

- Bottle labeling machine

- Volumetric filler

- Shrink wrapper

- Semi-automatic filler

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Multi-head filler

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeller for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.