Semi-automatic filling machine drumfor liquidswith mass flow meter

Add to favorites

Compare this product

Characteristics

- Operational mode

- semi-automatic

- Container type

- drum

- Product applications

- for liquids

- Type

- with mass flow meter

- Volume

Max.: 300 gal

Min.: 30 gal

Description

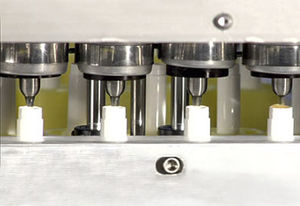

Designed for filling 30-300 gallon containers, the Flow Meter Filler for Drums and Totes offers the state of the art Coriolis Flow Meter technology to fill liquid by weight. No other filling technology offers this advanced combination of features and benefits. This system offers huge cost benefits and a high degree of flexibility. Mass Flow Meter technology has never been this affordable. The Coriolis Flow Meter technology can measure the mass (weight) of virtually any liquid. Changes in product viscosity, temperature, pressure, and specific gravity are compensated for automatically. This filling system can also provide sophisticated process control systems to track fill weights and product density in real time. This filling technology is the answer to controlling fill weight problems.

Standard Features:

(6) Sanitary Flow Meters with tri-clamp fittings

(6) Bottom-close Fill Head Valves to prevent drips

Servo Diving Fill Head Assembly, for bottom-up fills and height adjustment

316 stainless steel pressure vessel, mounted low for easy cleaning

CIP System, with spray ball in vessel, process program, and fill head trough

Sanitary Product Infeed Control Valve, air-to-open, spring-to-close actuator

Intuitive and Easy-To-Use PLC Control System

Allen Bradley PLC Control (Ethernet Capable)

Product weight set from operator interface

On-the-fly product weight adjustment

Servo controlled nozzle diving motion for bottom up filling

Tool less adjustments for rapid changeover

Clean product flow path (no moving parts, dead spots, gaps)

Modular construction allows for upgrades

100+ program recipes

Catalogs

No catalogs are available for this product.

See all of APACKS‘s catalogsRelated Searches

- Automatic filler

- Wrapping machine

- Liquid filler

- Automatic labelling machine

- Automatic wrapping machine

- Bottle filler

- Stretch film wrapping machine

- Food product filling machine

- Palletizer

- Volumetric filler

- Bottle labeling machine

- Semi-automatic filler

- Shrink wrapper

- Filler for the chemical industry

- Automatic shrink wrapper

- Multi-head filler

- Turntable wrapping machine

- Filler for the pharmaceutical industry

- Side labelling machine

- Filler for the cosmetics industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.