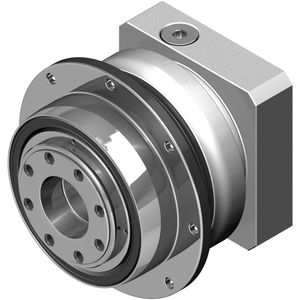

Planetary gear reducer AD serieshelical gearcoaxial200 - 500 Nm

Add to favorites

Compare this product

Characteristics

- Type

- planetary, helical gear

- Shaft orientation

- coaxial

- Torque

- 200 - 500 Nm, 20 - 50 Nm, 100 - 200 Nm, 50 - 100 Nm, 500 - 1000 Nm, 1 - 2 kNm, 10 - 20 Nm

- Configuration

- compact

- Performance

- high-precision, low-noise, low-backlash

- Applications

- transmission, shaft

- Other characteristics

- mounted, IP65

- Rotational speed

Max.: 10,000 rpm

(62,831.85 rad.min-1)Min.: 2,000 rpm

(12,566.37 rad.min-1)- Backlash

0.02 °, 0.05 °, 0.08 °, 7 °

- Gear ratio

Max.: 100 unit

Min.: 3 unit

Description

1. Helical Gear Design

Helical gearing increases the tooth to tooth contact ratio by as much as 33%,Benefits include increased torque capacity , ultimate smoothness , lower backlash and decreased noise. The helix angle is carefully chosen to gain these advantages while not producing excessive axial forces.

2. Triple-split collet and dynamically balanced set collar clamping system

Triple-split collet and dynamically balanced set collar clamping system for efficient power transmission. Perfect concentricity from one-piece sun gear / input shaft reduces backlash and allows higher input speeds.

3.Patented planet carrier design

Patented planet carrier design mounts the sun gear bearing directly into the planet carrier in order to eliminate misalignment. This exclusive design offers great advantages in decreased noise, vibration and transmission errors and losses.

4.One-piece carrier

One-piece carrier and output housing ensure 100% concentricity and alignment of all the rotating components. One-piece construction increases strength, rigidity and system reliability.

-

5. NYOGEL 792D

Lubrication by synthetic Nyogel 792D grease for smooth operation over the whole service life, Sealed to IP65 standard for ingress protection and can be mounted in any orientation.

6. In-house plasma nitriding heat treatment

Our In-house plasma nitriding treatment process allows the hardness of the gear flank to reach over 900Hv for superior wear resistance and still maintain a core hardness of 30HRc for toughness and resistance to shock loading

Catalogs

No catalogs are available for this product.

See all of Apex Dynamics‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Precision gearbox

- Compact gearbox

- Gear train gearbox

- Shaft gearbox

- Transmission gearbox

- Helical gear gearbox

- Single-stage gearbox

- Bevel gearbox

- Low-noise gearbox

- Multi-stage gearbox

- High-efficiency gearbox

- Two-stage gearbox

- Electric motor gearbox

- High-torque gearbox

- Flange gearbox

- Low-backlash gearbox

- High-precision gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.