- Industrial machines and equipment

- Heat Exchanger and Refrigeration

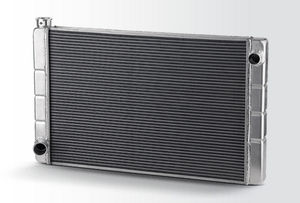

- Oil cooler

- API Schmidt-Bretten, API Heat Transfer group

Oil cooler air-cooledcustombrazed plate

Add to favorites

Compare this product

Characteristics

- Material

- oil

- Other characteristics

- air-cooled, custom, brazed plate

Description

Oil cooling requirements vary widely depending on the type of equipment and duty cycle required. We’ve specially selected fin and tube options to provide the exact performance and durability the application calls for. Whether its high viscosity start up or full temperature operation, our brazed aluminum oil coolers keep it cool. We carefully select each oil cooler to be compatible with your system and each product is carefully designed to provide you the best combination of heat transfer and pressure drop.

Oil Cooler Technologies

BAR & PLATE OIL COOLERS

We’ve identified the best selection of hot and cold fin combinations to provide the ultimate in flexibility and provide the best heat transfer performance in the market.

Highly flexible design options

Enhanced internal fin geometries for superior cooling

Wide variety of hot fins to balance internal pressure drop

High-efficiency louvered fins for superior heat rejection

Wide variety of debris resistant non-louvered fins

Specially designed extruded tanks withstand high pressures

Ideal for low viscosity fluids

Welded tanks for a long leak-free life

Integral bypass relief valves

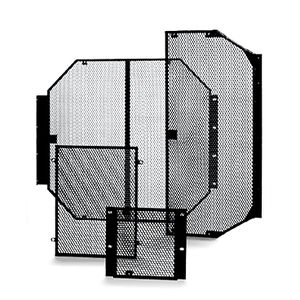

TBAR OIL COOLERS

Our patented TBAR replaces hot fins and bars with a single extruded tube for increased product durability.

Highly flexible design

Patented tube-to-bar joint ensures consistent brazing

Extruded tubes provide unrivaled durability & fewer leak paths

High-efficiency louvered fins for enhanced heat rejection

Debris resistant non-louvered fins

Specially designed extruded tanks withstand high pressures

Welded tank to core for a long leak-free service life

Zinc-Infused aluminum cores for unrivaled corrosion protection

Catalogs

No catalogs are available for this product.

See all of API Schmidt-Bretten, API Heat Transfer group‘s catalogsOther API Schmidt-Bretten, API Heat Transfer group products

Air Cooled

Related Searches

- API - Schmidt-Bretten cooler

- API - Schmidt-Bretten liquid cooler

- API - Schmidt-Bretten heat exchanger

- API - Schmidt-Bretten water cooler

- API - Schmidt-Bretten air cooler

- API - Schmidt-Bretten liquid/liquid heat exchanger

- API - Schmidt-Bretten industrial cooler

- API - Schmidt-Bretten plate heat exchanger

- Compact chiller

- API - Schmidt-Bretten tubular heat exchanger

- API - Schmidt-Bretten stainless steel cooler

- API - Schmidt-Bretten stainless steel heat exchanger

- API - Schmidt-Bretten gas/liquid heat exchanger

- Air-cooled recirculation chiller

- API - Schmidt-Bretten industrial heat exchanger

- API - Schmidt-Bretten oil cooler

- API - Schmidt-Bretten compact heat exchanger

- Process water cooler

- API - Schmidt-Bretten copper heat exchanger

- Air-cooled chiller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.