- Industrial machines and equipment

- Heat Exchanger and Refrigeration

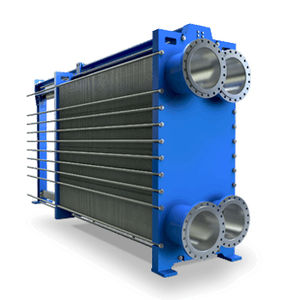

- Welded plate heat exchanger

- API Schmidt-Bretten, API Heat Transfer group

Welded plate heat exchanger Schmidt® SIGMAWIGliquid/liquidgas/liquidgas/gas

Add to favorites

Compare this product

Characteristics

- Type

- welded plate

- Fluid

- liquid/liquid, gas/liquid, gas/gas

- Material

- stainless steel, titanium, nickel

- Other characteristics

- high-performance, compact, high-pressure, gas cooler, low-pressure, corrosion-resistant, custom, for corrosive fluids, high-temperature, sanitary, condensation, seawater resistant, counter-current, water cooler, water-cooled

- Applications

- for the food industry, industrial, for heat pump, vaporization, for the chemical industry, for the pharmaceutical industry, for the petrochemical industry, for refrigeration, for hydraulic systems, for marine applications, for the food and beverage industry, for viscous products, for the plastics industry, exhaust gas heat recovery

- Power

Min.: 1 W

(3.41 BTU/h)Max.: 10,000,000 W

(34,121,400 BTU/h)- Operating pressure

25 bar, 35 bar

(362.59 psi, 507.63 psi)- Temperature

Min.: -40 °C

(-40 °F)Max.: 300 °C

(572 °F)

Description

Our line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many industrial applications.

Built entirely without gaskets or with an O-ring type gasket between the all-welded plate pack and frame, they provide exceptional corrosion resistance. The exchanger features corrugated plates that produce highly turbulent flow in a true counter-current direction. The result is high efficiency in a very compact design. Due to the smaller size and reduced material content, welded plate heat exchangers can be the most economical heat transfer choice.

Reduced Liquid Volume

The standard design has all piping connections located on one end of the heat exchangers. This simplifies installation and maintenance costs. Many times, the piping alone is all that is required to adequately support the heat exchanger, thus eliminating support considerations and labor costs in packaged equipment.

API Heat Transfer welded plate heat exchangers have narrow flow channels and reduced liquid volume needs. Due to their efficiency, they can be selected to use less coolant.

Reliable Heavy-Duty Construction

The exchanger design features plates with computer-designed corrugations in a “chevron pattern” that is alternated from plate to plate. This yields a strong, unitized construction. There are two options for incorporating the welded plate pack into the pressure frame. The plate pack openings are joined to the nozzles of the pressure frame or for frequent temperature fluctuation.

Catalogs

Other API Schmidt-Bretten, API Heat Transfer group products

Plate

Related Searches

- API - Schmidt-Bretten cooler

- API - Schmidt-Bretten liquid cooler

- API - Schmidt-Bretten heat exchanger

- API - Schmidt-Bretten air cooler

- API - Schmidt-Bretten water cooler

- API - Schmidt-Bretten liquid/liquid heat exchanger

- API - Schmidt-Bretten plate heat exchanger

- API - Schmidt-Bretten industrial cooler

- Compact chiller

- API - Schmidt-Bretten tubular heat exchanger

- API - Schmidt-Bretten stainless steel cooler

- API - Schmidt-Bretten stainless steel heat exchanger

- API - Schmidt-Bretten gas/liquid heat exchanger

- Air-cooled recirculation chiller

- API - Schmidt-Bretten industrial heat exchanger

- API - Schmidt-Bretten compact heat exchanger

- API - Schmidt-Bretten oil cooler

- API - Schmidt-Bretten copper heat exchanger

- Process water cooler

- Air-cooled chiller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.