- Production Machines

- Other Manufacturing Equipment

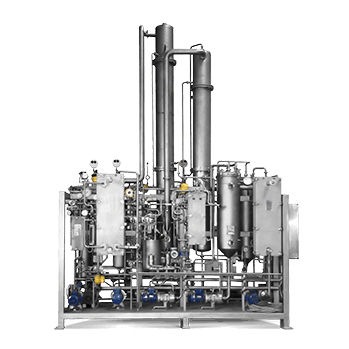

- Alcoholic drink distillation plant

- API Schmidt-Bretten, API Heat Transfer group

Alcoholic drink distillation plant Schmidt® SIGMATEC

Add to favorites

Compare this product

Characteristics

- Options

- for alcoholic drinks

Description

Our Schmidt® SIGMATEC Dealcoholization System has been designed for the dealcoholization of wine and beer. With experience in brewing that dates back more than 140 years, our SIGMATEC process represents another successful development in our line of Schmidt thermal systems. This new procedure uses continuous vacuum rectification to ensure a gentle removal of alcohol for a quality and enjoyable end product.

Advantages of SIGMATEC Dealcoholization Systems

Selective alcohol separation with minimal aroma loss

Gentle dealcoholization using low temperature vacuum technology

Complete dealcoholization to less than 0.1 % alcohol

Optimum adaptability to different products and formulations

Operation with hot water or steam

Performance data: 4-100 hl/h and more

Completely continuous and automatically controlled

No effluent problems

Industrial alcohol as subsidiary end product, ready for immediate marketing

Process Description:

After degassing, the product is preheated in our SIGMA plate heat exchanger and is then fed to the stripping section of a rectifying column.

The fluid flows down the column at a temperature between 43 and 48°C. Through counter flow, the product contacts rising vapors which bring about the selective separation of the alcohol from the product.

The alcohol free wine/beer is then fed from the bottom of the column into an evaporator. In the evaporater, vapors are produced, which are necessary for the rectification process. These are then redirected into the column. The completely dealcoholized product is pumped out of the plant via a cooler.

Catalogs

No catalogs are available for this product.

See all of API Schmidt-Bretten, API Heat Transfer group‘s catalogsOther API Schmidt-Bretten, API Heat Transfer group products

thermal systems

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.